Incremental path

| Technology levels and steps of the incremental path | |

|---|---|

| Level 0 | side products |

| Introduction of total positional control | xxx |

| Level I | side products |

| switch-over to stiffer materials | xxx |

| Level II | side products |

| introduction of practically perfect vacuum | xxx |

| Level III | basis for products advanced products maybe-products |

Up: Pathways to advanced APM systems

The incremental path towards advanced APM systems describes a desired process of slowly increasing technological capabilities (tools making better tools) with avoidance of loss of a strong orientation towards the far term goal of the stiff nanomachinery in gem-gum technology. This translates into starting off by using soft nanomachines to the fullest to get away from soft nanomachines ASAP.

The incremental path towards advanced APM systems is complementary to the direct path. The direct path to advanced APM systems in comparison describes a desired process of jumping to the advanced far term goal ASAP without significant detours. It is specifically focused on early usage of scanning probe microscopy for mechanosynthesis of diamond (or silicon) with throughput levels that are significant enough for the bootstrapping of a gem-gum factory. Following the direct path alone may be problematic.

- Sometimes a direction that on first inspection looks like it would lead fast to the goal actually does lead to it very slowly (or even not at all).

- Sometimes a direction that on first inspection looks as if it would lead only very slowly to the goal actually would lead to the goal fastest (which might still be slow).

This was the reason for the introduction of the distinction between direct path and incremental path.

Details on the critics towards the direct path will be located on the "direct path"-page.

As historical note there is also the Feynman path but as-is in its unmodified version

it is clearly not practical for several reasons

elucidated on the dedicated page linked above.

Contents

[hide]- 1 Dodge the trapdoors

- 2 High level map for the incremental path

- 3 Self-assembly – Climbing selfassembly levels

- 4 Base material – Climbing technology levels

- 5 Combining the best of different selfassembly technologies

- 6 Why positional control must be introduced before switchover to stiffest materials

- 7 Atomically precise positional control requires positional atomic precision

- 8 Terminology

- 9 Paths that are treated separately because its harder to find a concrete goal for them

- 10 Terminology for early systems

- 11 Related

- 12 External links

- 13 References

Dodge the trapdoors

Do not be fooled by the symmetry and scale of artificial self assembled molecule crystals!

What matters most is termination control. Especially on surfaces.

This is a way better (but less visually conspicuous and stunning) measure for technological progress.

This is in analogy to metallic or mineral nanoparticles.

Despite them having an atomically precise interior crystal structure they

are not being considered atomically precise because their surface geometry is usually a combination of ...

- a statistical distribution and

- a predetermined shape (usually simple convex polyhedra, sometimes constrained to 2D sheets or even 1D rods).

Also note: Self assembly of an arc into a full circle

can be considered as absence of termination control in angular direction

as angles are constrained to 360° by nature already.

When averting hitting the start when going around by 360° and thus going helical

a lack of termination control becomes trivially obvious if present.

High level map for the incremental path

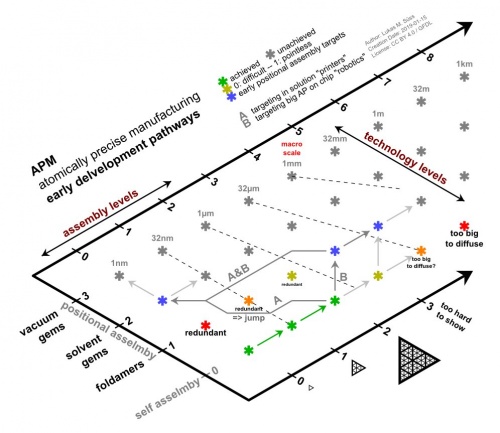

Left axis: technology levels

Right axis see: convergent assembly comparison and hierarchical self-assembly.

This map here plots:

- technology levels by use/control of material and means of assembly against ...

- assembly levels as in the degree to which hierarchical selfassembly has been achieved.

The starting-point of technological development/progression is the bottom-most asterisk-star.

Green asterisks mark ares where some results have already been achieved.

The window of escape

The argument this map-diagram here is trying to justify is that there might be kind of a

window of escape between the blockades in pathways of development (red, orange, and yellow) .

Blockades:

- The red, orange, and yellow stars tagged with "redundant" mean:

Everything that positional assembly can do here selfassembly can do equally well (yellow) or better (red). - The red, orange, and yellow stars tagged with "too big to diffuse" means:

Thermally driven selfassembly faces increasing problems due larger parts moving slower.

Starting out to the left right away is both

- technically hardly possible (noncomposable primitive selfassemblies hardly can introduce positional assembly) and

- economically not at all motivatable (due to the positional assembly redundancy blockade mentioned above)

Degree of directness of the indirect path

Note that there is kind of a degree of directness in the indirect path.

Directness in the sense of:

- How early/aggressively one attempts to take a hard tun left in the map-diagram.

- How early/aggressively one attempts to get to a positional assembly kinematic loop with proper separation of concerns

- How tightly one attempts to circumnavigate the positional assembly redundancy blockade.

- How far to run up against the diffusion slowdown blockade before taking the left-turn

Depending on the directness of the indirect path further sub approaches of the indirect path can be identified:

- Early-most leftward-turn: Catalysis construction kit approach

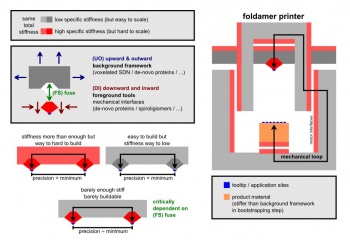

- Later leftward-turn: Printer approach (See: Foldamer printer)

- Very late leftward-turn: Robo approach (See: Modular molecular composite nanosystem MMCN)

Self-assembly – Climbing selfassembly levels

State of progress

A good place to look at is foldamer R&D specifically structural DNA nanotechnology.

Several noteworthy milestones have already been reached.

Metrics for progress

Bad metrics for progress (superficially impressive):

- symmetry of self-assembles

- size of self-assemblies

Good metrics for progress (more subtle):

- degree of termination control

- stiffness originating from geometry of formed structures

persistence length but in relative terms: (wikipedia)

Pushing against the limits of artificial self-assembly

What are the limitations to scaling up selfassembly?

- (A) more blocks taking more time to find each other

- (B) bigger blocks diffusing more slowly – The diffusion slowdown blockade

- (C) limits in implementability of sets of complementary interfaces where correct pair bind well but wrong pairs do not

- (D) wrong assembles not coming apart again – kinetic traps

- ... and certainly more

Counterstrategies:

- (1) using longer chain molecules to increase local effective concentration

– so done in some forms of SDN and always present in single chain self folding. - (2) Squigglesembly – using iterative self-assembly to getaway with small sets of complementary interfaces

- (3) Circumsembly – using parallel selfassembly pathways to circumvent selfassembly errors (that may be tolerable)

- (4) algorithmic selfassembly ...

- (5) going for nonthermal self-assembly at larger scales

- ... and certainly more

Base material – Climbing technology levels

The recently developed self assembling structural DNA nanotechnology and similar reliably designable foldamer structures might be a good starting point from technology level 0.

- By introducing robotic (more precisely stereotactic) control one could reach something like a "block level precision robotic technology" technology level I from there in a first step.

- In a second step one could change to e.g. Pyrite or Silica technology level II as building material to increase structural stiffness, reduce vibration amplitudes and get thus more placing accuracy.

- And finally in a third step one could switch from fluid phase to vacuum so that carbon and silicon can be assembled technology level III.

This very crude temporal outline is by no means the only possible way to go to eventually arrive at positional atomic precision.

There may be shortcuts or other paths. (See: Direct path)

Literature

In Appendix II of the book "Radical Abundance" [1] it is proposed to go through several levels of APM technology to reach advanced (positional atomic precision & diamondoid) APM.

These levels will serve as a rough guideline for the structuring of this Wiki.

In "Nanosystems" [2] technology stages are mentioned beginning with section 16.5.2. (written before the emergence of structural DNA nanotechnology).

Combining the best of different selfassembly technologies

Combining self assembly technologies could perhaps boost progress.

See main page: Combining advantages of different selfassembly technologies

Why positional control must be introduced before switchover to stiffest materials

For water synthesizable gemstone materials every crystal site looks exactly the same. Sites are featureless.

So to add atoms (or AP groups thereof) to such a crystal at desired locations (and there only),

the one single option available is positional assembly.

The same holds for materials made out of many identical small organic molecules.

Details:

- switch-over to stiffer materials at some point is critically dependent on

- introduction of total positional control ...

... this is because stiffer materials cannot afford to encode the position of their constitute parts within the shape of their constitute parts which is what selfassembly mandates as fundamental prerequisite.

Such position in shape encoding forces a minimum size of constitute parts and bonds weak enough to be suitable for thermal annealing averting kinetic traps.

But what about Biomineralization?

Does it not work without positional assembly?

In biology biomineralization is likely not atomically precise. Bones & teeth (apatite or calcium-phosphate), shells (calcite or calcium-carbonate), diatoms (silica) all have no need to be atomically precise. Variously sized batches of phosphate, carbonate, silicate, sulfate, ions are probably just dumped in the general location to push the concentration locally to levels of where percipitation starts happening.

(TODO: verify lack of AP in biomineralization)

Yes, there is biomineral with atomic precision in the active center of some proteins, but this is usually just a few unit-cells.

The protein provides a one-off specialized solution for this exact nano-crystal.

Atomically precise positional control requires positional atomic precision

Attaining positional control mandates going from mere topological atomic precision (no errors in what links to what) to actual proper positional atomic precision (sub building block sized resolution – possibly subatomic resolution).

Weaker: Placing super-atomar blocks (small molecules, stiff compact de-novo-proteins) only requites block level precision.

See: Lattice scaled stiffness

Terminology

Since a nanofactory at the endpoint of an incremental path will inherit the capability of handling at least the materials of one generation before it,

it may be better to call the products gemoid instead of diamondoid this terminology would make it more clear that gemstone like bio-minerals like quartz are included.

Paths that are treated separately because its harder to find a concrete goal for them

Note that the behavior of mobile electrons at the nanoscale is not as easily predictable as the behavior of mechanics at the same scale thus there's less exploratory engineering for nanoelectronics than nanomechanics. See:

- non mechanical technology path (including nanoelectronics)

- brownian technology path. (including things like synthetic biology)

[Todo: improve article quality]

Terminology for early systems

In Erics blog (2018-11-10) early foldamer based systems were referred to as:

"modular molecular composite nanosystems (MMCNs)"

One could also perhaps call them:

"coarse-block atomically precise systems"

Related

- Technology levels (axis to the left in diagram)

- Hierarchical self-assembly levels (axis to the right in diagram)

- Pathways to advanced APM systems

- Pathway controversy

- Bridging the gaps

External links

- Slides: "Toward Modular Molecular Composite Nanosystems" -- K. Eric Drexler, PhD -- U.C. Berkeley -- 26 April 2009 -- [1]

References

- ↑ Radical Abundance: How a Revolution in Nanotechnology Will Change Civilization - by K. Eric Drexler

- ↑ Nanosystems: Molecular Machinery, Manufacturing, and Computation - by K. Eric Drexler