Foldamer printer

This is a concept proposed by Eric K. Drexler.

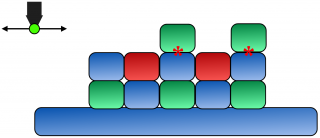

The idea is to build a fully self assembled nanoscale device

- that is remotely akin to a macroscale 3D printer.

- that capable of assembling more advanced materials within its "build volume" via

site activation assembly (a semi positional assembly approach)

Related: Printer approach

Components

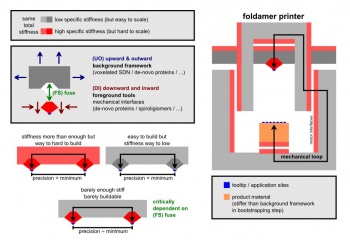

Structural framework

Proposed: de-novo proteins.

There are huge challenges in achieving meaningful scalability for de-novo proteins.

That is: It i hard to design a set of de-novo-protein-blocks that form a

general purpouse consrtruction kit for highly geometrical assemblies

with controlled termination of self assembly over larger scales.

A core issue here is that currently (2021) sets of de-novo proteins come

with very small orthogonal sets of interfaces.

Structural DNA nanotechnology:

- would likely be too soft. It's much softer than stiff proteins

- has possible attachment sites much more spaced out

Which is a shame because:

- it is capable of making quite cuboid (slightly twisted) structures

- it has quite a bit more meaningful sacability as of yet (2021)

Maybe it can be used if multiple foldamer technologies are combined.

Actuators Actuation

Proposed: Photo activated molecules.

There has been quite some progress in achivien seperate optical communication channels that have sufficiently low cross-talk.

All of these printers hit by the same light (many) would do the same in parallel.

Site activating tooltip

Still quite open question.

Depends on processed materials.

Processed materials

Still quite an open question.

- smaller stiff molecules like e.g. spiroligomers maybe?

- biominerals somehow?

- other de novo proteins?

Only if this enables assembly that would not be possible via selfassembly.

Otherwise this would defeat the purpose of the device.

Foldamer printers with positioning mechanisms could serve as "platforms" for an expanding range of chemistries and components.

Helping along in inching up the technology levels.

Bootstrapping advanced APM

Easier accessibility than direct path approaches

Foldamer printers as major milestone in the bootstrapping process towards advanced productive nanosystems.

The following is taken from the "Takaway" slide of Eric Drexlers presentation slides.

Arrows (▶) indicate word for word citations. Below these are some maybe more easily digestible explanations.

▶ Solution-phase operation can simplify system requirements

- Depositing material by wash in onto activated sites renders means for picking up parts unnecessary.

- (The foldamer printer being fully self assembled means there is no need for means for its positional assembly.)

▶ Mechanical functions can be reduced to tool positioning

With the need of picking up stuff removed making a relatively simple 3DOF positioning device

(akin to a 3D printer) is all that's needed for getting to a working device.

▶ Accessible structures and steppers can implement positioning

Accessible as used here means that we can make these things with

the experimental means that we have available today (or predictably rather soon).

This combined with the dformer basically says:

We can make the necessary stuff that is needed for such a foldamer printer already with today's means.

▶ The accessible design space includes attractive architectures

Some of the foldamer printer designs that should be possible should be really useful.

I guess that's whats this statement is about. Not 100% sure.

▶ Broad applications make the platform the most exciting product

Platform as used here means the solution full of many many assembled foldamer printers itself considered as a meta product.

A product whose main value lie in its ability to make other products

Self replication

This design is not dedicatedly aimed at self replicative capability and does not depend on it.

That said, the parts that it would make could be used to improve on next technological generations in a gradual fashion.

If eventually a point is reached where all parts of these foldamer printers are made by other foldamer printers

then the resulting devices would be qite on the compact end of the spectrum of self replicative systems.

- More compact than self replication on the second assembly level.

- Not as compact as the outdated concept of molecular assemblers since foldamer printers seem to depend on bigger pre-produced blocks.

A goal of these printers thoug is to aim towards assembly of more advanced materials with smaller stiffer building blocks.

Exactly such kinds of materials that cannot be made via selfassembly. Otherwise these printers would be pointless.

Misc

Products that are bigger than the build volume?

There are at least two options for doing this:

- nonthermal selfassembly making it ribosome like chain assembly

- positional for larger scale blocks by other means

Related

- Incremental path

- Printer approach - (wiki-TODO: Maybe merge pages.)

- Kinematic loop

- Foldamer printers could be part of Modular molecular composite nanosystems

External links

- Dr. Eric Drexler - The Path to Atomically Precise Manufacturing (timestamp 13:55)

Uploased to YT by The Artificial Intelligence Channel on 2017-09-18 - Dr Eric Drexler The Path to Atomically Precise Manufacturing (timestamp 13:55)

Uploaded to YT by Daniel Yarmoluk on 2018-01-22 - Archived on internetarchive: [1]

- Slides about the foldamer printer concept: [2]

5 August 2015 INFAPM Workshop, Office of Advanced Manufacturing, DOE