Site-specific workpiece activation

Instead of picking up stuff and then placing it to assemble something

site-specific workpiece activation works such that on the surface of a workpiece some spots are activated and then the

pieces that are meant to be placed on these now activated sites are washed in with some solvent gas (or other means).

"Activation" may mean different things in different instances.

There are at least two example cases for this.

One on the smallest physically scale and one on a bigger scale.

Bigger scale site-pecific workpiece activation

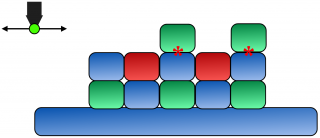

This is present as part of the proposed foldamer printer.

PALE patterned layer epitaxy (experimentally demonstrated)

The near atomically sharp needle tip of a scanning probe is used to abstract hydrogen from a silicon surface in an

positionally atomically precise way.

Subsequently silicon is deposited via gas phase.

Used scanning probes where all macroscopic and big (till before 2021)

miniaturization of scanning probes could speed up the process quite a bit.

This manufacturing method is related to the direct path.