Gemstone-like molecular element

Diamondoid molecular elements (DMEs) here also called crystolecules are structural elements or machine elements at the lower physical size limit. They are produced via mechanosynthesis and are often highly symetrical. Since exclusive use of metal atoms is unsuitable for nanoscale machine parts (metal-to-metal bonds are rather undirected and metal atoms on metal surfaces tend to diffuse away from where you've put them) stable diamondoid materials must be used. Diamondoid molecular elements are central in semi advanced and highly advanced atomically precise manufacturing (Note that beside classical gemstones bio-minerals fulfill the criteria for "diamondoidivity" too). Thanks to exploratory engineering it is proven that DME's with sliding interfaces work exceptionally well although they cannot be produced yet (state 2015..2016).

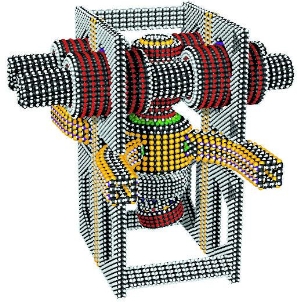

Check out some images of DME examples.

Contents

Beware of the stroboscopic illusion

| well animated bearing The fast thermal vibrations are more realistically blurred out. |

badly animated bearing The present stroboscopic effect can be misleading in that friction is likely to be grossly overestimated. It deceivingly looks like as if the operating speed would be close to the speed of the thermal vibration. If that where the case it indeed would cause massive friction (strong coupling of motions with similar frequency). |

Simulated DMEs often show a misleading stroboscopic effect making one believe that the operation frequencies lie near the thermal frequencies giving the false impression of enourmously high friction but actually the contrary is true - see "superlubrication".

Nomenclature

Since the here described physical objects have no official name yet (2016) something sensible must be invented to refer to them on on this wiki. Here we settle to the technical acronyms DMME, DMSE and DME (details below) and for usage in natural language the term "crystolecule" since a DME is somewhat of a cross between a crystal and a molecule. Crystolecules must not be confused with molecule-crystals (crystals made today out of folded up polypeptide molecules aka proteins that today are made to find the locations of their constituent atoms). To emphasize the distinction one could use the term "covalent crystolecules".

Technical acronyms:

- DME ... Diamondoid Molecular Element (stiff - small - minimal)

- DM machine elements (DMMEs) (examples) like e.g. bearings and gears have completely passivated surfaces.

- DM structural elements (DMSEs) (example) are minimally sized structural building blocks that are only partially passivated. They can expose multiple radicals on some of their surfaces that act as AP welding interfaces to complementary surfaces. The step of connecting surface interfaces is done in assembly level II and is irreversible.

Machine elements (DMMEs)

Types

Bearings

DMME bearings exhibit superlubrication. In the case of diamondoid rotative bearings this looks like described here: E.Drexler's blog: Symmetric molecular bearings can exhibit low energy barriers that are insensitive to details of the potential energy function.

The occurring friction is orders of magnitude lower than the one occurring when liquid lubricants are used in macro or microscopic (non AP) bearings E.Drexler's blog: Phonon drag in sleeve bearings can be orders of magnitude smaller than viscous drag in liquids.

DMME bearings can be built such that the force between bearing and axle is anti-compressive further lowering dynamic drag but also lowering stiffness possibly down to zero. E.Drexler's blog: Bearings can be stable despite attractive interactions between their surfaces (related: levitation)

If badly chosen the combined symmetry of bearing and axle can create a bistable tristable or an other low symmetry configuration. This should usually be avoided. Some symmetry considerations can be found here: Zyvex; Ralph C. Merkle: A Proof About Molecular Bearings and iirc on the Nanoengineer-1 developer wiki which went missing. :(

A tutorial on bearing design can be found here: A Low-Friction Molecular Bearing Assembly Tutorial, v1

Friction elements

Interlocking teeth with low stiffness can snap back and thermalize energy. E.Drexler's blog: Softly supported sliding atoms can undergo abrupt transitions in energy This can serve as a break (analog to an electrical resistor in an electrical circuit)

Gears

Single rows of protruding atoms can be used as gear teeth. But a simple pair of inter-meshing straight bevel-gears has a lot higher bumpiness than well designed DMME bearings. This can be reduced by making the gears very slightly helical (e.g. through applied strain) so that simultaneous contacts have phase shifts thoroughly below the angle of a tooth. Such bump-smoothing-gears have not been designed and analyzed yet (2014) [Todo: example design]. Meshing pairs of unequal designed gears may help too.

Making the teeth bigger by using more but not much more than one atom row for a gear gives a lot of undisired "bumpiness".

Quite a bit bigger gears could use involute teeth like their macroscopic cousins. Involute teeth can be approximated by strained and or dislocation including diamondoid structures. Surface structure is best kept non-aligning. Friction prone passivations like a standard hydrogen passivation should be avoided. Graphite linings might be usable. It remains to be analyzed whether and if which advantages approximations of involute and other gear profiles provide. The effects on transmittable torque, axial pressure and so on are of interest.

Considerations about stiffness as in superlubrication for DMME bearings are equally relevant for grears [more details needed].

Fasteners

Details can be found on the locking mechanisms page.

Enclosed radicals could be used to make very compact reversible connectors (name suggestion: covaconns - for covalent connectors)

- [Todo: note details about the expanding ridge joint]

Pumps

There is a model of a single atom neon pump which to some degree acts as a filter too. Positive displacement pumps like piston pumps scroll pumps or progressing cavity pumps have not yet been designed.

Others

- Parts for the management of semi diamondoid structures - e.g. coil barrels - those are especially amenable for testing.

- [Todo: telescoptc rods; joints; hinges .... ball joints -> issues lack of ball curvature?]

Sets

To be able to build the maximal amount of different microcomponents with the minimal amount of DMEs one needs to design/pick optimal sets of DMEs from a very large design space.

Minimal set of compatible DMMEs

In electric circuits there is one topological and three kinds of basic passive elements.

Adding an active switching element one can create a great class of circuits.

0) fork node; 1) capacitors; 2) inductors; 3) resistors

Those passive elements have a direct correspondences in rotative or reciprocating mechanics namely:

0) planetary or differential gearbox [*]; 1) springs; 2) inertial masses; 3) friction elements

[*] and analogons for reciprocating mechanics (see: Nanomechanic circuits)

But there are limits to the electric-mechanic analogy. Some mechanic elements often differ significantly from their electric counterparts in their qualitative behavior. Two examples of elements quite different in behaviour are:

- transistors & locking pins

- transformers & gearboxes

With creating a set of standard sizes of those elements and a modular building block system to put them together

creating rather complex systems can be done in a much shorter time.

Like in electronics one can first create a schematics and subsequently the board.

To do: Create a minimal set of minimal sized DMMEs for rotative nanomechanics. Modular housing structures standard bearings and standard axle redirectioning are also needed.

To investigate: how can reciprocating mechanics be implemented considering the passivation bending issue

Structural elements (DMSEs)

There's the shape-lock-chain-core-reinforcement principle. For details see: Structural elements for nanofactories

DME Adapters

It makes sense to have for each standard DME no matter of which type an adapter to a "the" standard couplings on the transportation chains. Since adapters will be reusable for many cycles the necessary production capacity for part-A-adapters will be much smaller than the targeted production capacity for part-A-DMEs. Building (mechanosynthesizing) the adapters right on the transportation chain couplings avoids the necessity of adapters for adapters.

Connections at this level will mostly be sparse covalent reversible and for a bit bigger parts Van der Waals and shape locking.

Sets

- standardised building block systems

- housing structures

- standard corner pieces connecting the various crystallographic planes

- in edge passivation with hydrogen can be problematic

- issue of non androgynous sinterfaces

- brackets for sub bond length positioning [[1]]

- standard pipe and channel segments - the passivation bending issue is of relevance

Molecular transport elements

Elements that create one dimensional structures for the logistic transport of different media are a bit of a cross between machine elements and structural elements.

data transmission

For transmission of data in Nanosystems polyyine rods where proposed. They constitute the thinnest physically possible rod manufacturable and consist out of sp hybridized carbon which must be mechanosynthesizable for their construction which goes beyond minimal necessary capabilities (sure?). Handling of sp carbon is involved in already analyzed tooltip chemistry though and thus likely to be available. Polyyne rods obviously are rather susceptible to radiation damage thus it might be wise to use chains of benzene rings which are more stable. With the first few additional ring widths the event of non self healing catastrophic damage becomes drastically more unlikely per unit of time. [Todo: calculate estimations] Still two of those ribbons like to fuse under UV irradiation (see: anthracene) Going to cyclohexan chains and bigger diamondoid rods makes the surface a lot more bumpy and the housings a lot more bulky.

- parity bits and more elaborate (somewhat holographic) data redundancy

- bit flip - tape rupture

energy transmission

For power transmission strained shell near cylindrical diamondoid axles are a good possibility reciprocative movement may be better for high power densities.

Heat transport

For thermal drain water works well because of its very high heat capacity. To drastically reduce friction one should pass it around enclosed in diamond pellets (capsule transport) to get it in either one needs to use very high pressure (sealing might be difficult; thermal conductance may suffer) or the insides are made hydrophobic by adding -OH instead of -H surface terminations. In the latter case mechanosynthetic oxygen placement capabilities are needed which go beyond minimal necessary capabilities. Pipes are easily creatable but work better at the macroscale. It may be possible to use the phase transition ice water to keep the factory at constant temperature but note that super-clean water (that occurs as waste see below) does not necessarily freeze when super-cooled and the melting point might be significantly altered in small possibly hydrophobic encapsulation.

raw material supply

For supply of solvated raw material the same method as for the cooling solvent can be used.

waste removal

A waste that always occurs at a low rate comes from oxidation of excess hydrogen - atomically clean water. Water can be drained via pipes or enclosed in pellets [more investigation of existing literature needed]

Beside that depending on how much self repair capability is included waste can be constituted out of shunned microcomponents because they are irreparable or likely to be broken or dirt contaminated. (see: "microcomponent tagging") or out of dysfunctional DMEs caused by assembly errors. ...

General properties of DMEs

To get a better picture how DMEs behave mechanically and in general how everything else behaves at this size range one can look at the scaling laws which describe how physical quantities scale with size.

DMEs with carbon, silicon carbide or silicon as core material can have internal structure like

- diamond / lonsdaleite

- or other possibly strained sp3 configurations.

Due to the lack of defects the ultimate tensile strength of larger DMEs lies above diamond of thermodynamic origin.

Strained shell structures

To form cylindrical or helical structures with high to maximal rotational symmetries for their size (good axles for superlubrication) one usually constructs wedge shaped segments and put them together until they naturally turn around 360 degree. Bending can be induced from internal structure or surface passivation (since passivation atoms haven't got the exact same bond length like the internal atoms, see: passivation bending issue). If 360° are exactly met the structures bending results from internal unstrained structure the whole structure is unstrained - a goal to aim for. If not bending to a strained shell is required. For thin tubes of high diameter a completely unstrained lattice of the used diamondoid material can be bent around. A note on bending tools can be found on the "mechanosynthesis" page.

Spheres are rather hard to approximate. [to investigate: feasability of ball joints]

VdW sticking

See: locking mechanisms

[Todo: add calculation of how much surface is needed to securely overcome the characteristic thermal energy (100kT?) -- to locking mechanisms?? -- techlevel I related too ...]

[Todo: link to force estimation]

Acceleration tolerance

[Todo: add calculation of a block on a neck model - for "intuitive" understanding]

When halving size mass shrinks eightfold (scaling laws) this leads to ...

high tolerance to accelerations (and possibly slow building speeds) may seduce one to build very filigree structures. Especially nanofactories will have lots of vacuum filled free space inside. Since the structures still can be crushed by external pinching forces one should - to avoid health hazards and waste production - always design with prevention measures for sharp edges and splinters in mind.

Design of MMEs / crystolecules

To this date (2015) most of the designed crystolecules where made with the software nanoengineer-1 When designing DMEs some things have to be taken care of. See: Design of Crystolecules

Related

External links

At K. Eric Drexlers website:

- A shaft in a sleeve can form a rotary bearing

- Sleeve bearings have been designed and modeled in atomic detail (here shown minus the stroboscopic illusion)