Tether assisted assembly

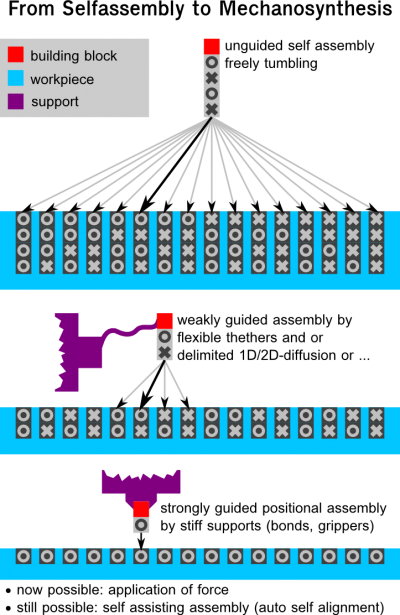

Up: Spectrum of means of assembly

Tether assisted assembly (or tether aided assembly or weakly guided assembly) is the weakest possible form of mechanosynthesis.

It involves only crude positional guiding to the target (placement) area.

Leaving the part to be placed lots of wiggle-room by holding and guiding it via a tether (flexible chain molecule).

Contents

Positional guidance with "snapping to target"

For reliable reactions there needs to be "snap to target".

That is: An energy energy neds to be dissipated that is >>kT.

Positional assembly atop highly localized (thermally driven) selfassembly

Optionally "last mile self assembly" may still be involved.

That is: Picking out the right reaction site by shape complementarity, but highly localized around the target site.

Encoding of position can be more compact as a smaller address space needs to be covered.

In case of "last mile self assembly" its callable a semi-mechanosynthetic process.

But better stick to "tether aided (local) selfassembly" or

(more general including other things too) weakly guided selfassembly.

Misc

It seems tether aided assembly is more suitable for assembly than for disassembly or site-specific workpiece activation.

Related

- Method of assembly => Thermally driven self assembly

- Mechanosynthesis (disambiguation) => Mechanosynthesis

- Introduction of total positional control

- Mechanosynelf assembly – sort of duplicate page