Difference between revisions of "Early diamondoid nanosystem pixel (direct path)"

m (→Semi reasonable seeming szenario) |

(→Related: added back-link to new page * System complexity scaling with positional assembly) |

||

| (14 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | {{wikitodo|Fix image. This is NOT a nanofactory pixel. There is no strong factory style optimizations yet.}} | ||

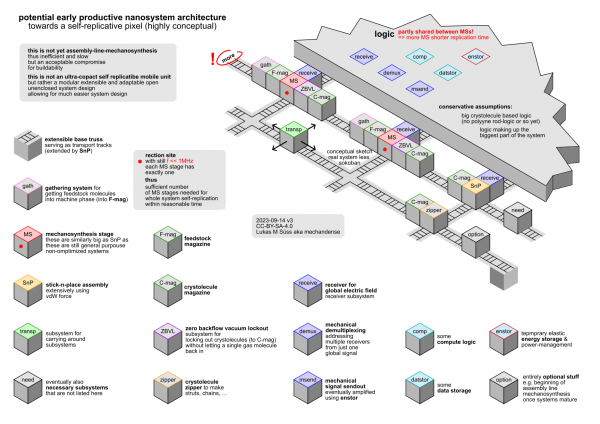

| + | [[File:PotentialEarlyNanofactorySystemArchitecture.png|600px|thumb|right|Conceptual sketch illustrating the idea of an '''"early diamondoid nanosystem pixel" or "early replicative pixel"''' for short. This is an attempt to evade the shortcomings of ultra-compact monolithic-machine molecular assemblers as [[bootstrapping]] tools. In order to find a perhaps more viable [[direct path]]. See: [[Proto-assembler (outdated)]]. Evading assemblers as described in the early [[Engines of Creation]] (but shunned in the technical analysis [[Nanosystems]]), Evading assemblers as presented in [[KSRM]], and evading assemblers as discussed in some designs that supposedly evade them but really just change to "stuck to surface". (See: [[Discussion of proposed nanofactory designs]].) '''Note that "stuck to a surface" is only a part of the distinction that is insufficient standing alone.''' – '''[[:File:PotentialEarlyNanofactorySystemArchitecture.svg|Link to vectorgraphic version.]]''']] | ||

| + | |||

This page covers considerations regarding an early crystolecule system <br> | This page covers considerations regarding an early crystolecule system <br> | ||

that can eventually approach non-compact selfreplicative capability. <br> | that can eventually approach non-compact selfreplicative capability. <br> | ||

| Line 40: | Line 43: | ||

Vacuum chambers for mechanosynthesis are hard non-expandable and as big as needed. <br> | Vacuum chambers for mechanosynthesis are hard non-expandable and as big as needed. <br> | ||

| − | They can be as big as permitted by the assembly mechanism. | + | They can be as big as permitted by the [[crystolecule]] assembly mechanism. <br> |

| − | Smaller might be | + | Smaller might be preferable for more modularity. |

| − | + | See main page "[[vacuum handling]]" for details on expelling the <br> | |

| + | fully mechanosynthesized and passivated [[crystlecule]]s out into clean air space. <br> | ||

Vacuum chambers are non-momolithic out of many crystolecules held together by <br> | Vacuum chambers are non-momolithic out of many crystolecules held together by <br> | ||

[[vdW force]] or [[form closing interlock]]. They are assembled in clean air. | [[vdW force]] or [[form closing interlock]]. They are assembled in clean air. | ||

| − | The vacuum just needs a single exponential | + | The vacuum just needs a single exponential pump-down using the <br> |

| − | lockout mechanism as positive | + | lockout mechanism as positive displacement pump. <br> |

| − | + | From then on no pumping is needed because the mechanism has <br> | |

| − | zero gas molecule | + | perfectly zero gas molecule back-flow during crystolecule lockout. <br> |

| + | Tunneling is [[FAPP]] ignorable. <br> | ||

| + | |||

See: [[Vacuum lockout]] <br> | See: [[Vacuum lockout]] <br> | ||

| + | |||

| + | === Why not a monolithic vacuum chamber? === | ||

| + | |||

| + | A monolithic vacuum chamber crystolecule would be a very big [[crystolecule]]. <br> | ||

| + | – Extremely (impossibly?) hard to make wit early SPM systems. <br> | ||

| + | – Also challenging for early nano-robotic mechanosynthesis. <br> | ||

| + | |||

| + | Beside the sheer size of the parts there is the issue hat the stage needs to <br> | ||

| + | fit into the camber yet also mechanosynthesize the chamber.<br> | ||

| + | Leading to wild expanding vacuum camber designs and such. <br> | ||

| + | Generally this is a driver towards more [[proto assembler]] like designs <br> | ||

| + | with all the associated problems waiting there. | ||

| + | |||

| + | Also big bespoke monolithic crystolecule designs design may set a bad precedent <br> | ||

| + | when it comes to "design for crystolecule reusability". <br> | ||

| + | See: [[Recycling]] and [[Gem-gum waste crisis]] | ||

== Potentially individually movable subsystems == | == Potentially individually movable subsystems == | ||

| Line 74: | Line 96: | ||

'''Crystolecule recomposition management subsystems:''' | '''Crystolecule recomposition management subsystems:''' | ||

| − | * part dispenser magazines carried carried on | + | * part dispenser magazines carried carried on wide attachment chains <br> giving a lot of part storage density like in movable libraries but faster access |

| − | ''' | + | '''Very early very simple automation:''' |

| − | * rail assembly factorylet | + | * rail assembly factorylet (crystolecule assembly to standard parts like: rails, struts, chains, …) (think: cranked box acting like a (un)zipper) |

== Machine elements == | == Machine elements == | ||

| Line 100: | Line 122: | ||

---- | ---- | ||

* Kind of an analogy along the [[incremental path]]: <br>[[Modular molecular composite nanosystem]] | * Kind of an analogy along the [[incremental path]]: <br>[[Modular molecular composite nanosystem]] | ||

| + | ---- | ||

| + | * [[self replication]], [[bootstrapping]], [[autogenous]], [[bridging the gaps]] | ||

| + | ---- | ||

| + | * '''[[Mixed path]]''' | ||

| + | * [[Incremental path]] analogy: '''[[Modular molecular composite nanosystem]]''' | ||

| + | * [[System complexity scaling with positional assembly]] | ||

== External links == | == External links == | ||

Good inspiring sources. <br> | Good inspiring sources. <br> | ||

| − | A lot needs to be adapted to the nanoscale physics and context. | + | A lot needs to be adapted to the nanoscale physics and context. <br> |

| + | Most electrics needs to be replaced by mechanics which is perhaps the most challenging part (and perhaps the most volume consuming part). | ||

| + | |||

| + | === Moses2013 === | ||

| − | |||

Self-replicating blocky-granular gantrybot pick-n-place robots on a square grid of rail-tracks. <br> | Self-replicating blocky-granular gantrybot pick-n-place robots on a square grid of rail-tracks. <br> | ||

See [[Moses2013]] | See [[Moses2013]] | ||

| − | + | ||

| − | Ambots | + | === Ambots === |

| + | |||

| + | An interesting modular system architecture with some relevant aspects: | ||

* [https://www.youtube.com/c/AMBOTS3D/videos Ambots on YouTube] | * [https://www.youtube.com/c/AMBOTS3D/videos Ambots on YouTube] | ||

* [http://ambots.net Ambots landing page] | * [http://ambots.net Ambots landing page] | ||

| + | |||

| + | Note that Ambots has a specialized unit that is just for carrying otherwisely specialized units around that can not move on their own. <br> | ||

| + | Ambots wheels on flat ground would not be feasible for nanoscale at all of course. <br> | ||

| + | Rather than a lot of self contained autonomy in the Ambost case <br> | ||

| + | in the case here (reversible) mechanical coupling to drive chains in a rail network via clutches is needed. <br> | ||

| + | Reciprocative chains for signalling could even be as simple as cuboids in a channel. Not even interlocking. <br> | ||

| + | The trick being using vdW-force and/or push-back spring at the end. | ||

| + | |||

---- | ---- | ||

__TOC__ | __TOC__ | ||

Latest revision as of 14:14, 19 November 2024

(wiki-TODO: Fix image. This is NOT a nanofactory pixel. There is no strong factory style optimizations yet.)

This page covers considerations regarding an early crystolecule system

that can eventually approach non-compact selfreplicative capability.

This page is not about molecular assemblers.

Specifically not ones in the bootstrapping context: Proto-assembler (outdated).

Also not about molecular assemblers stuck onto a chip like in some old concepts (Chris Phoenix 2003).

See: Discussion of proposed nanofactory designs.

Semi reasonable seeming szenario

Positive formulation:

- a non-compact system expanding to the size it wants to be in order to eventually reach selfreplicativity

- an open-exterior nano-system, i.e. there's no vacuum box enclosing an eventually "replicative unit pixel"

(see vacuum handling below) - an non-monolithic open-borders nanosystem (i.e. components from adjacent "replicative unit pixel" can cross over to collaborate)

- strong separation of concerns in sub-systems e.g. a carrier chassis just to carry subsystems around

Due to non-compactness:

- enough space to balance mechanosynthesizers with stick-n-placers (Level throughput balancing)

- enough space for eventual early automation where ist makes sense

e.g. specialized automated strut crystolecule assembler factorylets

Regarding automation & functional redundancy:

Note that this is by no means an advanced mature factory style nanofactory with yet.

No one-atom-per-station operations and such.

Any functional redundancy from throughput balancing and limited automation is solely to

increase feasibility of buildability and to facilitate faster system scaling.

Early nanoscale quantity sellable products would help in

making this pathway more ecomomically feasible though.

Making some of the above for-scaling-necessary-optimizations easier.

Negative formulation: Unlike an molecular assembler

- not ultra-compact in volume - not forced in a box of desired size

- no expanding vacuum hull - and no box enclosing the whole system as part of the nanosystem

- no monolithic closed-borders design (i.e. adjacent subsystems can cross over)

- no whole system mobility

Vacuum handling

Only the mechanosynthesis happens in PPV (assembly level 1).

Assembly of crystolecules to assemblies of them (assembly level 2) is done in clean air.

For that a macroscale enclosing cleanroom box (or anything better) suffices.

Vacuum chambers for mechanosynthesis are hard non-expandable and as big as needed.

They can be as big as permitted by the crystolecule assembly mechanism.

Smaller might be preferable for more modularity.

See main page "vacuum handling" for details on expelling the

fully mechanosynthesized and passivated crystlecules out into clean air space.

Vacuum chambers are non-momolithic out of many crystolecules held together by

vdW force or form closing interlock. They are assembled in clean air.

The vacuum just needs a single exponential pump-down using the

lockout mechanism as positive displacement pump.

From then on no pumping is needed because the mechanism has

perfectly zero gas molecule back-flow during crystolecule lockout.

Tunneling is FAPP ignorable.

See: Vacuum lockout

Why not a monolithic vacuum chamber?

A monolithic vacuum chamber crystolecule would be a very big crystolecule.

– Extremely (impossibly?) hard to make wit early SPM systems.

– Also challenging for early nano-robotic mechanosynthesis.

Beside the sheer size of the parts there is the issue hat the stage needs to

fit into the camber yet also mechanosynthesize the chamber.

Leading to wild expanding vacuum camber designs and such.

Generally this is a driver towards more proto assembler like designs

with all the associated problems waiting there.

Also big bespoke monolithic crystolecule designs design may set a bad precedent

when it comes to "design for crystolecule reusability".

See: Recycling and Gem-gum waste crisis

Potentially individually movable subsystems

This is obviously hopelessly incomplete ATM.

Core subsystems

- modular expandable base rail-grid

- electrostatic receiver (static motors?)

- mechanical demultiplexer

- subsystem carrier chassis (moving motors? motor backpack)

- mechanical through joint motion threading

(challenging as this crosses systems)

Assembly stages:

- crystolecule stick-n-place stage

- mechanosynthesis stage (eventually with gas-tight walls and zero-backflow airlock)

Basic compute – cam follower unit for nonlinear robot control ?? – stepper control stuff? coarse to fine swithcing ??

Crystolecule recomposition management subsystems:

- part dispenser magazines carried carried on wide attachment chains

giving a lot of part storage density like in movable libraries but faster access

Very early very simple automation:

- rail assembly factorylet (crystolecule assembly to standard parts like: rails, struts, chains, …) (think: cranked box acting like a (un)zipper)

Machine elements

These are the sub-systems of the sub-systems.

Typically many off them rigidly connected.

See: Crystolecule based machine elements

Related

- Why ultra-compact molecular assemblers are too difficult

- Why ultra-compact molecular assemblers are too inefficient

- Why ultra-compact molecular assemblers are not desirable

- Pixel in mature systems: Gem-gum factory pixel

- Kind of an analogy along the incremental path:

Modular molecular composite nanosystem

- Mixed path

- Incremental path analogy: Modular molecular composite nanosystem

- System complexity scaling with positional assembly

External links

Good inspiring sources.

A lot needs to be adapted to the nanoscale physics and context.

Most electrics needs to be replaced by mechanics which is perhaps the most challenging part (and perhaps the most volume consuming part).

Moses2013

Self-replicating blocky-granular gantrybot pick-n-place robots on a square grid of rail-tracks.

See Moses2013

Ambots

An interesting modular system architecture with some relevant aspects:

Note that Ambots has a specialized unit that is just for carrying otherwisely specialized units around that can not move on their own.

Ambots wheels on flat ground would not be feasible for nanoscale at all of course.

Rather than a lot of self contained autonomy in the Ambost case

in the case here (reversible) mechanical coupling to drive chains in a rail network via clutches is needed.

Reciprocative chains for signalling could even be as simple as cuboids in a channel. Not even interlocking.

The trick being using vdW-force and/or push-back spring at the end.