Difference between revisions of "Recycling"

m (→General) |

m (→Usage of microcomponents) |

||

| Line 15: | Line 15: | ||

== Usage of microcomponents == | == Usage of microcomponents == | ||

| − | Diamondoid Mechanosynthesis is an irreversible process. Once a [[diamondoid molecular elements|DME]] is assembled it can not be taken apart again (see [[atomically precise disassembly]]). The only way for the bound carbon back to the biosphere is by [[diamondoid waste incineration|burning]] it at sufficiently high temperatures (See the ''speculative'': "[[hot gas phase recycling cycle]]"). What will help alleviating this problem is the organisation of APM products into [[microcomponents]] (which are quite a bit bigger than [[diamondoid molecular elements|DMEs]]) that can reversibly be joined together and thus can potentially be reused and recomposed. More about those [[microcomponents]] can be found on the "[[assembly levels]]" page. [[microcomponents|Microcomponents]] only need to run through the upper basic assembly levels of a nanofactory ([[microcomponent recomposer]]) to get recomposed to a different product. | + | Diamondoid Mechanosynthesis is an irreversible process. Once a [[diamondoid molecular elements|DME]] is assembled it can not be taken apart again (see [[atomically precise disassembly]]). The only way for the bound carbon back to the biosphere is by [[diamondoid waste incineration|burning]] it at sufficiently high temperatures (See the ''speculative'': "[[hot gas phase recycling cycle]]"). What will help alleviating this problem is the organisation of APM products into [[microcomponents]] (which are quite a bit bigger than [[diamondoid molecular elements|DMEs]]) that can reversibly be joined together and thus can potentially be reused and recomposed. More about those [[microcomponents]] can be found on the "[[assembly levels]]" page. [[microcomponents|Microcomponents]] only need to run through the upper basic assembly levels of a nanofactory ('''[[microcomponent recomposer]]''') to get recomposed to a different product. |

[[microcomponent tagging|Tagging]] microcomponents can help to successfully salvage | [[microcomponent tagging|Tagging]] microcomponents can help to successfully salvage | ||

Revision as of 23:04, 27 February 2015

Contents

Recycling of early productive nanosystem products

The materials used in early bio based productive nanosystems (e.g. DNA) are completely bio degradable and production volumes probably won't be very high. Beside possible health issues there are vew problems with recycling to expect.

Biominerals that might be used by an intermediate level of productive nanosystem stay around longer but already naturally occur in masses in nature. Volumes of production and recycling issues are yet hard to predict.

In advanced productive nanosystems that is diamondoid nanofactories it gets problematic.

Diamond e.g. doesn't really decay. This is good for engineering but bad for nature.

Recycling of diamondoid AP structures

Usage of microcomponents

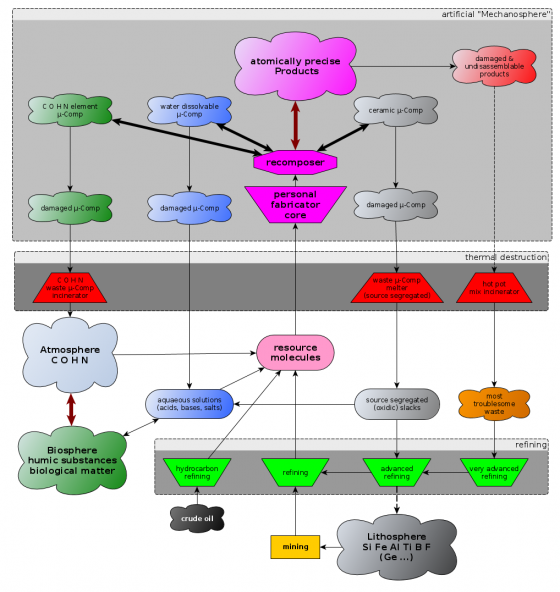

Diamondoid Mechanosynthesis is an irreversible process. Once a DME is assembled it can not be taken apart again (see atomically precise disassembly). The only way for the bound carbon back to the biosphere is by burning it at sufficiently high temperatures (See the speculative: "hot gas phase recycling cycle"). What will help alleviating this problem is the organisation of APM products into microcomponents (which are quite a bit bigger than DMEs) that can reversibly be joined together and thus can potentially be reused and recomposed. More about those microcomponents can be found on the "assembly levels" page. Microcomponents only need to run through the upper basic assembly levels of a nanofactory (microcomponent recomposer) to get recomposed to a different product.

Tagging microcomponents can help to successfully salvage microcomponents from macroproducts that became singed or broken with random fracture plane.

Inter microcomponent joints that do not destroy themselves (or some of the involved microcomponents) when ruptured are preferable in most applications where maximum strength isn't a necessity (splinter prevention). For this either trivial sticking of coplanar surfaces (Van der Waals force) or specially designed controlled breakage locking mechanisms suffice. If the joints are too weak and do not break in big chunks collectively (through whatever implemented mechanism) rub-off microcomponent dust may be an health issue.

Influence of nanofactory design on recycling

If a nanofactory does vacuum lockout from seperate compartments at the soonest possible moment in the convergent assembly chain - that is as soon as all open radicals are closed - the products are enforced to consist of microcomponents which are potentially recylable by recomposition into other patterns. The downside is that you have to deal with dirt.

If a nanofactory does convergent assembly right up to the full product size it can (it does not necessarly need to but it makes sense) delay the final vacuum lockout right to the very end of the production. If intermediate vacuum lockout layers are omitted the product might be a monolithic diamondoid block that can't be recycled at all and is probably hard to burn too. The reason why this is attractive for developers is that you can simplify design when you don't have to deal with dirt and grit.

One could call a nanofactory that is a failure in this regard an "eternal waste brick nanofactory" if such a design is the first one to spread massively it could mean disaster.

Reuse of microcomponents

Assuming a speculative global microcomponent redistribution system will come into existence then for big immobile objects beyond the weight of an adult person (like buildings) it may be possible to "suck" them away if they are no longer needed. For everyday sized objects running arround having them physically tethered to such a network will often not be possible (e.g. backpacks, drinking cans).

Preference of machine phase

Beside being a necessity for APM in all technology levels but t.level 0 keeping everything in machine phase also prevents spill of AP micro- and nanoparticles (that is microcomponents and DMEs) in the envirounment. The rule to never let go of diamondoid products (never let them escape the machine phase) to keep the biosphere clean obviously has to be dropped at some size level arond the millimeter scale though. In many cases its convenient when makro products come preassembled (laptop) but there are also cases where finding the most pleasing form of assembly is most intuitive and easiest done by hand (art). Such manual assembly of diamondoid AP products will maybe be doable by e.g. (speculative) quasi welding.

- semi-intelligent microcomponent metamaterial designed to allow abrasion only in big chunks ?

General

Advanced well designed AP Technology will probably greatly reduce the amount of waste that escapes in the environment. (Speculative) The most critical time is maybe when technology level III arrives but is not yet advanced. Recognizing and cropping out nests of damaged microcomponents will be a rather nontrivial problem. See "self repairing systems".

Production of waste that is irrecoverable at its production time is unavoidable. (Even nature lacking human influence faces this problem. See: great oxygenation event) What we can do is to try to limit the rate of irrecoverable waste production to such low levels that technology is likely to catch up to that challenge before the pollution grows beyond all bounds. Something like a dynamic equilibrium. (Is there a general principle waste removal capability always lags behind waste production capability? - Just guessing.)