Difference between revisions of "Direct path"

(→Difficulties / hurdles: moved quite a bit over to new page Early prototyping of piezochemical mechanosynthesis) |

m (→Current state) |

||

| Line 101: | Line 101: | ||

== Current state == | == Current state == | ||

| − | The most advanced part of the direct path currently (2017-06) seems to be the | + | The most advanced part of the direct path currently (2017-06) seems to be the technology of <br> |

"patterned layer epitaxy" aka "patterned atomic layer epitaxy" (patterned ALE) or more specific: hydrogen depassivation lithography (HDL)<br> | "patterned layer epitaxy" aka "patterned atomic layer epitaxy" (patterned ALE) or more specific: hydrogen depassivation lithography (HDL)<br> | ||

(HDL was first demonstrated by Prof. Joe Lyding of University of Illinois at Urbana-Champaign in 1994) | (HDL was first demonstrated by Prof. Joe Lyding of University of Illinois at Urbana-Champaign in 1994) | ||

Revision as of 23:44, 1 August 2024

The direct path is a second pathway to advanced APM systems beside the incremental path.

The objective of the direct path is to attain APM capabilities without the detour over bio-derived and solution phase systems (Skipping directly to vacuum gemstone metamaterial technology).

Contents

- 1 Phases of the direct path

- 2 Scaling approaches

- 3 Side products

- 4 Benefits from results of direct path development attempts

- 5 Direct path & critique with more or less sound basis

- 6 Difficulties

- 7 Current state

- 8 Build platform size extension

- 9 Two types of DME design

- 10 Relation to the incremental path

- 11 Direct path and molecular (proto)assemblers

- 12 Related

- 13 External Links

Phases of the direct path

The direct path can be divided up into two parts:

- development of tip based mechanosynthesis (demonstrating methods that circumvent the fat finger problem)

- scaling atomically precise systems up to macroscale size (via bootstrapping methods)

using diamondoid crystolecule parts only (no foldamers)

Here in this wiki the "direct path" will refer to both phases combinedly.

Merely the first phase alone may be part of a mixed path.

(wiki-TODO: Factor the page apart according to these two phases.)

- Early prototyping of piezochemical mechanosynthesis

- Direct path scaling to macroscale productive nanosystems

Scaling approaches

One (maybe rather hard) approach towards advanced gem-gum technology is to skip the outlined technology levels of the incremental path and try to create at least one necessarily very small and simple hydrocarbon robotic mechanosyntesis core** from which via exponential assembly a nanofactory can be spawned.

This proto-linkage/proto-manipulator approach is conceptually very near the early naive and now obsolete since hard-to-access inefficient and undesirable proto-assembler concept. The far opposite end of the spectrum complementary to the (maybe equally bad) completely non-directed far too slow "reach gem-gum-tec by accident" extreme end of the incremental path.

A little less ambitious but still very challenging approach would be to improve MEMS SPM technology so far that it is fast and accurate enough that arrays of it are able to produce early atomically precise productive nanosystems in sufficiently massive parallelism for early very low throughput products.

Perhaps most realistically though it seems that the direct path will be massively accelerated by opening up and using results of the incremental path. That is instead of using MEMS to pick and place atoms in the future it might be used to pick and place bigger assemblies form structural DNA nanotechnology de-novo protein technology or similar.

Side products

A major driving aspect for progress along a pathway are products that are perceived to be potentially profitable in a relative short term.

The incremental path can "easily" provide such motivation with medical applications that historically have been cash cows.

Well at least some accidental progress from that. It can be a strong distraction from progress on the pathway too.

For the direct path in comparison it seems harder to find early products for potential investors.

Some potential early products here include e.g. Metric standards. (wiki-TODO: add more potential early products for the direct path)

Quantum devices that critically depend on atomic precision and are valuable even with products of very low atom count.

Question is what kind of quantum devices.

Benefits from results of direct path development attempts

Experiental (and theoretical) proof of principle for far term goal strongly guided mechanosynthesis.

Showing that …

- the fat finger problem is not a show stopper even with currently available crude blunt tips with barely known structure and that …

- the sticky finger problem is actually not a problem. The "stickyness" helps instead.

Direct path & critique with more or less sound basis

Eric Drexler very early on (soon after his first book "Engines of Creations" EoC) abandoned the idea of the extreme end of the direct path: molecular assemblers (often also incorrectly referred to as simply nanobots). There's not a single word about molecular assemblers / nanobots in his technical book (Nanosystems). It's all about the identification of a sensible far term goal based on well understood physics (exploratory engineering) which resulted in the nanofactory concept. There's no complete bootstrapping plan included just a few hints for starting points that where visible back then.

In popular media though the old molecular assembler meme where stuck and furthermore gained its own mythology of omnivoric and evolving synthetic life. In the meantime a slew of researchers had annexed the fund bringing term "nanotechnology" that E.Drexler originally used in his first books to refer to quite different ideas. The researchers did this unknowing of both E. Drexlers work and unknowing or ignorant about the growing media mythologies. When the media began pestering scientists about dystopic mythologies though and they actually where working mostly on stupid (in the sense of their capabilities) nanoparticles they understandably panicked. Fearing loss of funding public uproar and maybe even terrorism.

They traced back the idea starting from the mythologies on the surface back to the still naive ideas in EoC. Already annoyed from the highly unscientific starting point and due to serious scientists time constraints they did not bother to check into the details of E. Drexlers newer more thought out technical work (Nanosystems).

This lead to reactions along the lines of: "Nanobots are far too dangerous but don't worry they are impossible"

Which is (in a perspective of more than a few years) false in several ways:

- Nanobots are a super-set of the here referred to hypothetical "rouge molecular assemblers". Nanobots include medical nanobots which will become possible pretty much for certain.

- It seems there might come up motivations for rouge self replicators (not exactly molecular assemblers) and they seem to become possible when the state of the technology will be advanced sufficiently far (far off future).

- When the time is ripe for rouge self replicators to emerge (as said far off future) they will be far less dangerous than the horror fairy tale depictions. Limits of "techno-ecological" niches; Presence of gradually introduced countermeasures, ...

In short:

The strong prominence of the extreme end of the direct path twisted into mythologies lead to rather unproductive critique of Atomically precise manufacturing (APM)

Back when this clash happened the incremental path towards gemstone metamaterial technology may have seemed very obscure and unfeasible to the scientists. With the recent breakthroughs in structural DNA nanotechnology that rapidly go into the regime of diffusion control and suppression this slowly seems to change though.

The incremental path lies on the other end of the development approach spectrum. This was and still is the route Erik K. Drexler strongly prefers. While the direct path may bring some benefits he sees the direct path mostly as a distraction (source book "Radical Abundance") which's perception has hindered development more than it has helped it. (See pathway controversy)

Difficulties

- providing resource materials like ethine and germanium source stuck to a surface but close together and near the building site is nontrivial

- for tool-tip recharge cycles more sites are needed

- how to isolate specific areas from potentially requited gas phase process steps

- currently reachable vacuum levels are not quite sufficient - encapsulation of a small working volume is hard

- macroscopic AFMs are accurate enough (when drift compensated on reference points) but too way too slow

- microscopic AFMs/STMs may be fast enough but are not as accurate yet

- coordinating multiple tips is actively researched but barely possible and very slow

- operation of current UHV system is painstakingly slow - days to weeks

- patterned layer epitaxy uses a thermodynamic process between de-passivation steps limiting reliability. [to check]

- with patterned layer epitaxy breaking loose movable parts seems difficult because: it seems hard to create overhangs, controllably breakable sparse tack down bonds and adjacent closely contacting passivated surfaces.

- replenish-ability

- harsh CVD conditions (when used)

- ...

Furter discussion of the individual issues by people knowledgeable in those areas is needed.

Current state

The most advanced part of the direct path currently (2017-06) seems to be the technology of

"patterned layer epitaxy" aka "patterned atomic layer epitaxy" (patterned ALE) or more specific: hydrogen depassivation lithography (HDL)

(HDL was first demonstrated by Prof. Joe Lyding of University of Illinois at Urbana-Champaign in 1994)

The (at this time published) structures have still high error rates and are mostly two dimensional. But they are on the strongly covalently bonding target material silicon and made at relatively high temperatures (that is not liquid helium). That is unless structures are not annealed at high temperatures (which current UHV systems often require) undesired surface reconstruction can often be avoided. (wiki-TODO: reference the paper that theoretically analyzes surface reconstruction)

At lower temperatures and with weaker bonding materials (mostly metals) more advanced atomically precise manupulation has been demonstrated. A very impressive example is an atomically precise memory (wiki-TODO: add link/ref)

Note that this is all 2D ony !!

The incremental path is far ahead in this regard.

Build platform size extension

On natural crystals atomically flat areas have only limited size. For CVD grown diamond this is even more so than for silicon. The size of facets should at least provide enough space for the assembly of tool-tips. If the capability to form overhangs is present one can build an inverted pyramid (sparsely filled to save time) to gain a perfectly flat surface of grater size.

Two types of DME design

Depending how direct one assumes technology level III is acessible one may choose from two voluntary design restrictions.

Those are A pure hydrocarbon structures (with sparsely included germainum allowed [add ref]) and B structures incorporating various nonmetals for e.g. elegant surface passivations from second and third row of the periodic table.

- If one assumes skipping of technology levels will succeed first a plethora of pre-existing right of the bat buildable structures will be very helpful.

- If one assumes incremental technology improvement will lead us further nonmetal including structures can provide a "final goal" sketch

- in reality somewhat in-between might happen.

Both choices have reason to be made and should probably be followed in parallel.

Relation to the incremental path

Link to the articles "Toward Advanced Nanotechnology:..." from K. Eric Drexlers Blog.

At the beginning of the research and exploratory engineering for advanced APM the hurdle to overcome the barrier to gain mechanosynthetic capabilities in the form of technology level III (the now outdated concept of assemblers was the primary model back then) was underestimated by many. The gap between the nature of biological systems and the nature of the target technology seemed to be too big to bridge in any foreseeable way. Thus by many an approach through direct tip based manufacturing with macro/microscopic tools (and some minimal chemical synthesis) was and still is seen as the primary route to go.

With new developments in the "nature inspired" molecular science department the mentioned gap closed down to a point where the further path became more foreseeable. With "new developments" what is meant here is mainly structural DNA nanotechnology (but also some other areas). This is actually quite far from biology. An "artifibiological" intermediate link one could say.

Still it's hard to say whether the direct path is competitive or not. At least it will certainly contribute in the form of "working down from the other side". Capability of chemical synthesis of tool-tips for diamondoid mechanosynthesis (following link suggested) will be very valuable.

Direct path and molecular (proto)assemblers

There are two kinds of molecular assemblers hat should be clearly distinguished

but especially from the direct path perspective the two are often discussed without heeding this.

Molecular assemblers as advanced productive nanosystems (outdated)

There is the case of molecular assemblers being proposed as supposedly optimized ideal far term target.

This view is outdated. As explained on the page Molecular assembler.

Molecular assemblers as bootstrapping pathway (difficult/impossible)

There is the case of (very primitive) molecular proto-assembler being proposed as

a supposedly viable bootstrapping pathway.

Being an early system clearly excused being far from optimal.

But the approach of a proto-assembler is extremely difficult (likely impossible).

Direct path without ultra compact molecular assemblers

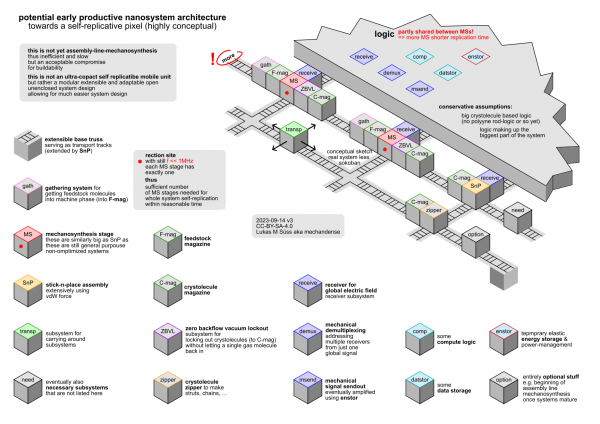

More distributed self-replicative systems (replication pixels using two assembly levels)

may have a better chance for viable bootstrapping.

Also more distributed systems may grow mutually beneficially together with parts of the incremental path

in later stages of technological development eventually.

But when it comes to which part to take the fronts are still hard (as of 2023) both technically and in peoples opinions.

Related

- Pathways to advanced APM systems

- Scanning probe microscopy

- Can electron beams from transmission electron microscopy be used to do at least low throughput early atomically precise manufacturing? See: "Quasi atomically precise techniques" for a discussion.

- There was a proposal on syntesizing tooltips for diamondoid mechanosynthesis and growing cone extensions by CVD methods. (wiki-TODO: add link -- was it "how to make nanodiamond" ?) (wiki-TODO: check if there was some followup work)

- Positional assembly

External Links

Recently more or less active projects that may focus more on the direct path

- nano.gov DOE: Atomically Precise Manufacturing FY 2018 (Some focus on the incremental path too.)

- Video: (2015-08-5/6) Proposal for Atomically Precise Manufacturing by the US Department of Energy (old dead link 1)

from the INTEGRATED NANOSYSTEMS FOR ATOMICALLY PRECISE MANUFACTURING WORKSHOP – AUGUST 5-6, 2015 (seems it has been removed from public view by 2023-05)

Citation: "The US Department of Energy (DOE) Advanced Manufacturing Office (AMO) hosted a Workshop on Integrated Nanosystems for Atomically Precise Manufacturing (INFAPM) in Berkeley, California, August 5-6, 2015." - Atoms to Product (A2P) - Darpa [1]

- The company zyvex (zyvex LABS) is working more on the direct path end of the spectrum of approaches.

Here's zyvex's page about Atomically Precise Manufacturing

- University of waterloo about DARPA's older tip based nanofabrication (TBN) program -- funded 2011-2013 (?)

- DARPA's newer "atoms to products" program [2]

- zyvex is involved with making nanotube boats for fighting pirates

General discussions that may relate more to the direct path

- Micro-Electro-Mechanical system Atomic-Force-Microscopes (MEMS-AFMs) (available since early 2017) icspcorp.com (microscopic microscopes for the masses)

Some related discussion: [3] - Video: (2013-10-18) John Randall - Atom by Atom Manufacturing Making atomically perfect materials and machines

- How To Make a Nanodiamond: A Simple Tool for Positional Diamond Mechanosynthesis, and its Method of Manufacture (January 27, 2006 by Robert A. Freitas Jr.)

- Pathway to Diamond-Based Molecular Manufacturing (2004-10-22 Robert A. Freitas Jr.)

Wikipedia

- atomic layer epitaxy ALE aka ALD (needs to be combined with atomically precise patterned depassivation to allow for the creation of atomically precice structures.)