Difference between revisions of "VdW suck-in"

m (→Related) |

(added image) |

||

| Line 1: | Line 1: | ||

{{Stub}} | {{Stub}} | ||

{{site specific term}} | {{site specific term}} | ||

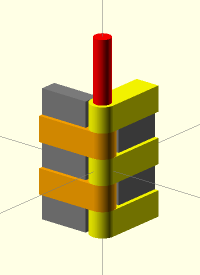

| + | [[File:Hinge self assisted assembly demo.png|200px|thumb|right|VdW force is "sucking" the pin into the sleeve. No retention structures neded as they would be needed for the macroscale.]] | ||

[[Van der Waals force]] can be very useful in advanced [[gemstone]] based nanosystems to hold things in place | [[Van der Waals force]] can be very useful in advanced [[gemstone]] based nanosystems to hold things in place | ||

* during assembly processes or | * during assembly processes or | ||

| Line 13: | Line 14: | ||

By choosing contact area profiles (easier for planar surfaces) one can emulate all kind on nonlinear spring behaviors. | By choosing contact area profiles (easier for planar surfaces) one can emulate all kind on nonlinear spring behaviors. | ||

| − | |||

* {{wikitodo|Add image of extendable soap bubble skin in rectangular wireframe}} | * {{wikitodo|Add image of extendable soap bubble skin in rectangular wireframe}} | ||

* {{wikitodo|Add math showing that at room-temperature thermally activated axle displacements are negligible even for very small crystolecules}} | * {{wikitodo|Add math showing that at room-temperature thermally activated axle displacements are negligible even for very small crystolecules}} | ||

Revision as of 13:34, 18 September 2022

Van der Waals force can be very useful in advanced gemstone based nanosystems to hold things in place

- during assembly processes or

- even in final products.

In particular the VdW force can be uses to hold axles withing chains.

Axles literally get "sucked" into their sleeves as the higher surface contact area means lower energy.

This is very similar to surface tension energy.

So unlike a (hooks law) linear spring where force is proportional to displacement

one gets a near constant force over displacement.

By choosing contact area profiles (easier for planar surfaces) one can emulate all kind on nonlinear spring behaviors.

- (wiki-TODO: Add image of extendable soap bubble skin in rectangular wireframe)

- (wiki-TODO: Add math showing that at room-temperature thermally activated axle displacements are negligible even for very small crystolecules)

A note on sticking strength

The strength of VdW bonds is not to be underestimated.

Weak bonds can be shaken open by thermal motion from heating. But ...

It does not take much contact surface area at all such that

the required temperature would be so high that

the gemstone base material would start to melt (or decompose) before the contact sticking becomes shaken apart.

Much boosted by the situation that the wole crystolecule made from many many atoms

does just get kT energy for each of it's few DOFs of motion.

- (wiki-TODO: Make a temperature vs area chart for diamond to diamond planar contact)

Related

- Van der Waals force sticking - (wiki-TODO: fator parts out to this page)

- Van der Waals force

- Energy, force, and stiffness

- Comparison of mechanical character of different bonds types

- Intuitive feel

- Crystolecules