VdW suck-in and suck-on

(wiki-TODO: Evetually split off a page: Solid state surface tension. (And vdW suck-on?))

Van der Waals force can be very useful in advanced gemstone based nanosystems to hold things in place

- during assembly processes or

- even in final products.

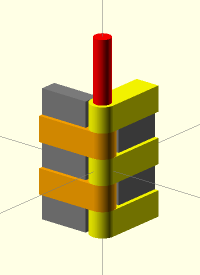

In particular the VdW force can be uses to hold axles withing chains.

Axles literally get "sucked" into their sleeves as the higher surface contact area means lower energy.

This is very similar to surface tension energy.

So unlike a (hooks law) linear spring where force is proportional to displacement

one gets a near constant force over displacement.

By choosing contact area profiles (easier for planar surfaces) one can emulate all kind on nonlinear spring behaviors.

- (wiki-TODO: Add image of extendable soap bubble skin in rectangular wireframe - and explain the analogy)

- (wiki-TODO: Add Philip Turners final oscillator simulation too and the matching position & speed charts - as this shows the constant force spring nature nicely)

Contents

[hide]A note on sticking strength

The strength of VdW bonds is not to be underestimated.

Weak bonds can be shaken open by thermal motion from heating. But ...

It does not take much contact surface area at all such that

the required temperature would be so high that

the gemstone base material would start to melt (or decompose) before the contact sticking becomes shaken apart.

Much boosted by the situation that the wole crystolecule made from many many atoms

does just get kT energy for each of it's few DOFs of motion.

- (wiki-TODO: Make a temperature vs area chart for diamond to diamond planar contact)

Reated to: Intercrystolecular interactions

Estimating thermally driven slide-out quantitatively

Math showing that at room-temperature thermally activated axle displacements are negligible even for very small crystolecules:

Let's assume a pin with a diameter of ⌀1nm:

From Nanosystems we know that the

VdW-energy surface-energy-density between diamonds is

ε = 200zJ/nm² (for silicon instead it is: ε = 700zJ/nm²)

Question: What is the expectation for the

axial slide-out h corresponding to E = k * 300K?

d * π * h * ε = k T

h = k T / (d * π * eps)

h = 4.14zJ / (1nm * π * 200zJ/nm^2)

h = 6.6pm (crudely!)

Van der Waals alone is more than sufficient.

Even for smallest axles and all nondestructive temperatures.

Tenfold room temperature in Kelvin (300K => 3000K) still

gives only a mere 66pm expectation for the slide-out distance.

For reference the length of a (C–C) bond in diamond is 154pm.

Even short pins will be significantly longer.

Experimental demonstrations

Stacked patterned nanographene vdW suck-on:

In [1] they nanomachined graphene stacks into various more or less precise shapes (not atomically precise).

Then they tested these by shifting and rotating layers. Observed was bots:

- superlubric misalignment sliding of sufficiently low friction to allow vdW such-on

- commensural interdigitation hookup preventing sliding

Some side-notes: This seems exciting as it seems close to what would be expectable in intercrystolecular interactions in terms of …

- shapes (more or less precisely cut disks),

- motions (translative and rotative "suck-on")

- scales (400nm very roughly 2000 C atoms)

Compared to nanotubes:

- More (easily early acessible non AP) design freedom?

- May be more easy to couple to yet smaller truly AP atom-by-atom built systems

- More in place manufacturable than nanotubes? Not that in place manufacturing restrictions are good.

Nested nanotubes vdW suck-in:

In [2] nested nanotubes have been spanned over gaps,

the outer shell(s) has/have been broken and

the inner shells have been exposed by a force form the drag from an airflow.

When stopping the airflow vdW suck-in pulled the outer sheets all the way on again.

While the nanotubes are nanoscale in cross-section they were large micro-to-macro mesoscale in length (almost a millimeter).

They were made optically visible by condensing some elemental sulfur as small droplets on them.

Notes on terminology

– vdW suck-in – vdW suck-on … seems better for cases where it's not like a piston in cylinder geometry – solid state surface tension … this would be more general (and explicitly points to a good source on intuition)

Related

- Solid state surface tension, vdW suck-on

- Van der Waals force sticking - (wiki-TODO: factor parts out to this page)

- Van der Waals force

- Energy, force, and stiffness

- Comparison of mechanical character of different bonds types

- Intuitive feel

- Crystolecules

Accidental heatpump:

When suck-in blocks thermal degrees of freedom the energy contained in these degrees of freedom may get "squeezed out" leading to a heat-up.

reversely a pullout can open up degrees of freedom and lead to a cool-down.

This thermal free energy is likely instantly dissipated and thus permanently lost.

Intercrystolecular snapping modes:

vdW suck-in force can cause snaps directly or indirectly removing steric blockades.

External links

Surface tension is a good intuition for sliding type VdW forces:

Here's a short video on YouTube @FluidDynamics

Here's another longer video demo on youtube @fyzlab.

Note that in the video due to the small area and large relative area change the membrane gets thinned out by a lot

this leads to a non-constant increasing force and rather than a constant force

which in turn allows for balancing with the constant force that is gravity.

VdW force on the other hand has no such thinning out effect and is constant.

- Wikipedia: Surface tension

- Wikipedia: growing surface graphic

- Tweet about related math: https://twitter.com/mechadense/status/1529798765854564352?s=20&t=CM0IGEpcOo67KRC3eG7dMA

References

- ↑ Koren, Elad; Lörtscher, Emanuel; Rawlings, Colin; Knoll, Armin W.; Duerig, Urs (2015). "Adhesion and friction in mesoscopic graphite contacts". Science. 348: 679–683. Full text.

- ↑ Zhang, Rufan; Ning, Zhiyuan; Zhang, Yingying; Zheng, Quanshui; Chen, Qing; Xie, Huanhuan; Zhang, Qiang; Qian, Weizhong; Wei, Fei (2013). "Superlubricity in centimetres-long double-walled carbon nanotubes under ambient conditions". Nature Nanotechnology. 8 (12): 912–916. doi:10.1038/nnano.2013.217.