General purpose positional assembly stage

A general purpose Nanoscale positional assembly stage for APM needs sufficient precision and accuracy to allow for the assembly of atomically precise nanostructures of structures that would not be easily (or at all) accessible via self-assembly.

Note: Positional assembly subsuming position and possibly orientation too, i.e. pose.

Contents

[hide]Resolution requirements

Note that for incremental path approaches via foldamer based systems

there is not necessarily a need to reach subatomic resolution

to reach topological atomic precision or even positional atomic precision.

Some allowed and possibly even desired thermal wiggle can help in centering effects.

There is also the rarely talked about option of tether assisted assembly.

Geometry options

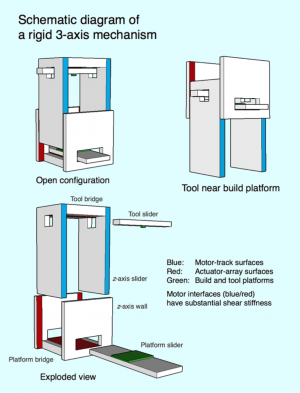

Rigid body robotics has a huge design space thus various geometries are possible.

Sufficient stiffness is critical though to suppress thermal motion wiggle amplitude allowing for atomically precision in the assembly with low enough error rates.

Potentially needed periphery

- feedstock supply

- waste removal

- data in

- data out

- data demultiplexing

- some status bit storage

- temporary energy storage

- maybe locally reversible actuation

- structural base framework (for maximal observability via macroscale means in bootstrapping context)

Direct path pros/cons

Cons

Periphery needs may be more difficult to provide than in the case of the incremental path.

A significant of an early diamondoid nanosystem pixel (direct path) might be neded to run a nanoscale

General purpose positioning stage.

Only thing missing to emergence of overall distributes system self-replicative capability

is a convergent assembly (second assembly level) which may by then be already present.

Pros

Top-down naoelectronics (not atomically precise)

may be able to provide heterogeneous data IO access.

Incremental paths pros/cons (in bootstrapping context)

Pros

Incremental path can cheat a bit with the periphery as

feedstock can be washed in waste can be washed out.

And one can take the site activation trick.

Cons

Structural stiffness and low noise deterministic actuation seem

like a particular difficult challenges for foldamer based positional assembly stages.

Speed/throughput (in advanced optimized gemstone based nanosystem context)

Advanced productive nanosystems will rather use molecular mills for

the base-load of part production as these can be orders of magnitude faster.

A few general purpose positioning stages can still be useful for

some final surface modifications requiring more complex paths

or individualized post processing of standard parts.

Related

- positional assembly (Tether assisted assembly)

- positional atomic precision

- topological atomic precision

- Specialized purpose molecular mills