Gemstone-like compound

in the future we will build with gemstones

Gemstone like materials encompass all materials that:

- have their atoms not moving around on their surfaces at room temperature but have them stay where they are for decades to eons. (they do not diffuse)

- are stiff enough to keep their shape under thermal movement at room temperature (this excludes all of today's plastic polymeres)

- have dense three dimensional networks of covalent bonds like gemstones - (short bond loops prevent rotations around single bonds)

Gemstone like materials include many neo-polymorphic compounds that currently can't be produced.

Possible alternatives for the term "gemstone like": gem-like, gemstoneoid, gemoid

Contents

[hide]Introduction

Why the focus on gemstone like compounds

The main reason why gemstone like (diamondoid) materials are the material of choice for diamondoid molecular elements DMEs (the constituents of artificial advanced AP systems) is that they do not jitter and wobble or even diffuse away while they are built with stiff manipulators which is a blind process that cant see or correct errors (open loop control). More specifically one needs to choose a gemstone like compound that is sufficiently stiff such that a manipulator made out of this compound can keep the amplitudes of the thermal vibrations that occur at the manipulators tip sufficiently smaller than the lattice spacing of the work-piece that is made out of the same (or an other) gemstone like compound. This way placement errors can be suppressed.

Also products out of gemstone like (diamondoid) materials can be made so that they only have one to a few tightly controlled degrees of freedom (axles rails). This way one can more easily test one action at a time. A fundamental engineering principle tat allows for faster progress. In contrast a systems design that poses the necessity for scientific entangling of convoluted relationships is usually considered bad. Natural nanosystems (e.g. living cells) are like this because of random incremental evolution in small steps without any far lookahead. In this regard one obviously shouldn't copy from nature.

Stability against water and other chemicals

Gemstone like compounds that are intended to be used on the surface of products have additional requirements on chemical stability. First and foremost in most cases one wouldn't want them to be water soluble. But resilience against stronger acids bases and oxidizers may be desired too. This drastically restricts the range of usable compounds. The majority of the material though lives well isolated on the inside of the bulk product. Thus for most of the products the wider less chemically stable range of material is open for usage. (extensive usage water dissolvable materials out of non toxic elements may even help biodegradability. Products should be designed in a way that Non-dissolvable nanoscale parts shouldn't come loose this way though!

Difference to normal gemstones and relation to metamaterials

By mechanosynthesizing gemstone like materials one can go far beyond the known polymorphs (or allotropes which are the polymorphs of single element compounds). One can go far beyond all the phases that are reachable by conventional thermodynamic means that lack atomically precise control. The newly accessible phases include thermodynamically unstable but strongly metastable ones.

The bigger the patterns the more the materials become low level metamaterials. It may not be possible to draw an entirely sharp line towards high level metamaterials.

Low level metamarterials include very stable patterns that are highly ordered. Those patterns may include vacancies and may have periods of repetition of arbitrary length. Their structural alterations are small enough to influence properties that originate at such low size levels e.g. chemical electrical magnetical and other properties (especially relevant for the non mechanical technology path). A simple example of a low level metamaterial is when donation atoms are embedded in a checkerboard or other exactly periodic pattern. The set of sufficiently metastable low level metamaterials is significantly bigger than the set of designed materials that can today (2014) be cooked together by macroscopic means. This set of designed materials favors random mixing because they require very restrictive good thermodynamic accessibility.

The distinction between low level metamaterials and high level metamaterials may be difficult in some cases. Conventionally doped semiconductors for example are not called metamaterials.

Carbons versatility

By the time of writing (2014) and the time of last review (2015..2017) carbon is the only building material for which extensive studies about tooltip chemistry have been undertaken.. Note that just by structuring just carbon (and adding a bit hydrogen as passivation agent) many material properties will be archivable.

Beyond carbon from acetylene and methane many further studies are needed most importantly:

- machanosynthetic splitting of water for scavenging usable oxygen

- direct splitting of oxygen

- splitting of nitrogen - artificial and different to current natural or industrial methods of nitrogen fixation.

- splitting of carbon dioxide

- fluorine and the nonmetal elements of the third period

Carbon nanotubes can replace the scarce element copper for electrical cables.

gemstone-like vs diamondoid

Instead of "gemstone like compound" the term "diamondoid compound" can be used.

This may have a more restrictive meaning limiting focus towards compounds that are easy to passivate and thus more suitable for machine elements with sliding interfaces. This primarty entails the exclusion of salts (like e.g. Periclase MgO) and secondary the exclusion of big class of metal oxides, sulfides, nitrides and related compounds (e.g. Sapphire, Pyrite, titanium nitride (Osbornite), ...)

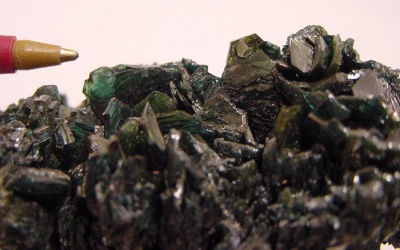

Gemstone like compounds

Please keep in mind that all compounds we know of today are only those few we can create by mixing and cooking various elements or preproduced compounds together. With mechanosynthesis many more will be accessible. Although they're not in a thermodynamic minimum they'll be very stable at room temperature. A recent example is the theoretical prediction of the stability of graphitic pentagonal carbon sheets with the so called cairo pattern. The "few" compounds we can create by mixing and cooking them together are all the minerals that are documented today. These will be surveyed here. Many more meta-stable compounds will become mechanosynthesizable though for most applications the allotropes of carbon used in their high level metamaterial configurations alone will suffice.

Taking the rock forming mineral quartz one finds several natural polymorphs - the "quartz group" beyond those natural polymorphs Neo-polymorphs of SiO2 will be accessible which are (albeit their deviation from thermodynamic equilibrium) very stable but not accessible today.

Lists of potential structural compounds

early materials

- gem-like biominerals ... compounds that are synthesizable under solution are of interest for technology level II to bridge the gap between technology level I and III.

pure elements

- C carbon sp3 network allotropes: diamond, diamonds known properties, lonsdaleite; sp2 allotropes: fullerenes, graphitic networks

- Si silicon (also cubic or hexagonal)

- B ~four allotropes of elementar boron (may be difficult to use)

- P & S allotropes of phosphorus and sulfur (may be difficult to use because of what follows below)

some classifications: (a high dimensional overlapping space of possibilities)

- Binary gem-like compounds

- Gem-like compounds that contain (partially abundant) s-block metals

- Ternary and higher gem-like compounds

- cubic garnets

- refractory materials

- Gem-like compounds containing elements of the 13th group

- high pressure modifications

- electrically conductive gem-like compounds

Issues with more complex compounds

Metamaterials made from the basic gemstone-like materials are able to emulate a lot of physical properties.

Further binary ternary or higher gemstone-like materials can complicate engineering design due to:

- low symmetry in their crystal structure - See: Isotropy of materials

- porousness due to bridge bonding like present in all salts of oxoacids X-O-X (X can be e.g. Si,Al,P,...) and some other compounds

- complex or polar surface structure which may be difficult to passivate

- lack of tensile strength

- ...

thus they may predominantly find use for special applications like as:

- slowly water dissolvable materials for better biodegradability

- laser gain materials

- infill materials

- materials with special electrical magnetical or other exotic non high level emulatable properties

- ...

In the following classifications section you'll find a lot of links to wikipedia articles about gem-grade minerals with very beautiful pictures. Please note that the colors you see are in most of the cases due to small impurities and not inherent to the minerals themselves. Most (electrically non conductive) minerals will be completely transparent when built defect and impurity free. An extreme example is silicon carbide known as a black solid but in single crystalline form it's called mossianite and completely transparent. Color should be intentionally addable by mechanosynthetic sparse checkerboard dotation.

compounds which contain relatively scarce elements

Those may be useful in the lower technology levels or special tooltip chemistry where only very small amounts are needed (e.g. germaium containing tips).

- molybdenium oxide structures

- germanium compounds

- ... many more

Sources for elements

Carbon is planned to be drawn from [ethyne] more commonly known as the welding gas acetylene. It has the advantage of a triple bond that when partly split up provides four unpassivated bonds and it's carrying around a minimal amount of hydrogen. Since DMEs are compact and crystal like they have a lot less surface than the source molecules and thus require a lot less hydrogen passivation. Ethyne cant be delivered in highly compressed gasseous form since it explosively decomposes. It is hardly soluble in water but well soluble in acetone ethanol or dimethylformamide. Ethyne can be manufactured by the partial combustion of methane and thus potentially be gained from renewable resources.

If one looks at the most common or most easily accessible elements and their simplest compounds one finds a list of potential structural building materials:

Link to a graphic of the most common elements in the earths crust from Wikimedia Commons.

Most easily accessible are nitrogen oxygen and argon since they can directly be drawn from the atmosphere.

To investigate:

- Means for filtering/capturing N2 and O2 each selectively from the atmosphere.

- Mechanosynthetic tooltips and manipulations to gain reactive moieties out captured N2 and O2.

drawn from the atmosphere

Oxygen and nitrogen rich compounds like SiO2 and Si3N4 are interesting because more than half of this material can be drawn directly from the atmosphere. When atmospheric carbon dioxide is used carbon allotropes and β-C3N4 can be drawn 100% from the air.

back to the atmosphere

When burning diamondoid materials (hopefully in a smart way - thus only in traces - see recycling) it strongly depends on the type of chosen material whether they convert to gasses or just reform to a glassy slag. In the latter case it will be more difficult to recover the elements in pure form. The rough rule is: When heated under oxygen mainly carbon based materials burn up almost completely while silicon or metal oxide based materials just melt to a slag. Everything in between could be possible. Certain combinations of elements can become dangerous when burned together as we know from the PVC dioxine problem.

Chlorine

Chlorine could be drawn from common salt leaving behind sodium. To get this residual into a nonreactive environmentally acceptable form that could be used as structural material rather than just constituting waste one could chose from sodium minerals. To prefer are compounds with no crystal water and simple formulas with only elements of high importance for APM (that is which we are likely to gain control of soon after reaching technology level III) like e.g. jadeite and further ones to find.

The 13th group

Elements of the 13th group (the boron group) are special in that they can form electron deficiency bonds.

If elements of this group come into play (are used in DMEs) the view of atoms as construction blocks with a fixed number of connection points breaks down. E.g. when boron comes in contact with nitrogen the lone pair of nitrogen plucks into the electron deficient hull of boron making the two atoms more behave like two four valenced carbon atoms (with a little polar/ionic character). Prime example: ammonia borane. This is not yet handeled correctly by the software Nanoengineer-1 so it is advised to refrain from using 13th group elements for DME design for now.

In high quantities both solvated aluminum and boron compounds are alien to human and natural biology. Intake can lead to bad or unknown effects. Thus one might refrain from using strongly water soluble compounds of 13th group elements. Some information can be found here: boron and water (de); aluminum and water (de)

In tooltip chemistry boron and aluminum may be useful as tool-tips for the handling of atoms with almost full electron shells like oxygen fluorine sulfur and chlorine effectively increasing their normally low bond number. (To verify!)

Related

- Semi diamondoid structures

- Find diamondoid compounds by the elements they contain.

- Mechanosynthesis

External links

Todo

- add some beautiful images of minerals in their gem grade form

- pseuso phase diagrams

- add nanosystems definition of "diamondoid"