Design of gem-gum on-chip factories

- (folding)

- Assembly levels give a great aid in nanofactory design.

- Tooltip preparation zone - Mechanosynthesis core - DME assembly robotics

- Design levels

Contents

Convergent assembly

Convergent assembly is not a means to speed up production.

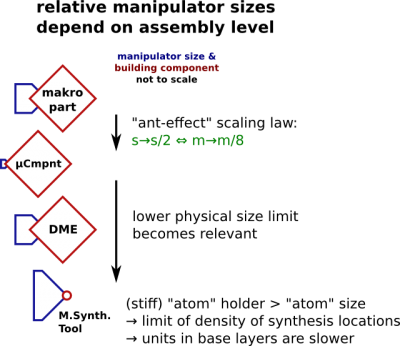

The lowermost three convergent assembly steps follow naturally from the character of the technology - see assembly levels.

Convergent assembly steps further up can be motivad by:

- more simple construction of overhangs without the need for scaffolds

- the automated management of bigger logical assembly-groups

- the simpler decomposition is standard parts that can be put together again in completely different ways

- the possibility to keep everything in a vacuum till the final product release - this should not be necessary and may decrease the incentive for the creation of systems that are capable of recycling

Do not confuse convergent assembly with exponential assembly which is an entirely different thing.

Nanosystem units

Robotic manipulators

Threading by systems

Cooling, vacuum and other logistics

Macroscopically separating design considerations

assembly level 0 splits up in capturing resource molecules from liquid phase by sorting mills and mechanosynthetic peparation. It makes sense to do the former in a warm and the latter in a cold environment. Makorscopic separation (possibly in seperate devices) can be considered. (Aerogel?)

- cooling & isolation

Although diamondoid mechanosynthesis works at room temperature cryogenic cooling will probably be employed just because it seems rather easy to do (see: "Diamondoid heat pump system") and error rates can be shrunken by many orders of magnitude.

General nanofactory design method

Given a set of "base units" for different components of the bottommost assembly levels their combination to form a full nanofactory unit can be determined by first finding the relevant quantitatively or at least qualitatively (set of choices) of evaluable relevant metrics and determine numbers of base units and branching factors based thereof. (constraint logic programming - prolog library clpqr?) might be useful. level throughput balancing output frequency of an assembly level == input frequency of the assembly level directly above

Design metrics

Performance limits

The ultimate performance limit is determined by the accepted dissipation heat at the lower levels the maximal acceptable accelerations at the higher convergent assembly levels. Designs leading to practical speeds at human scale lie way below the performance limits.

power dissipation is only a limiting factor at the bottommost assembly levels. At higher assembly stages bearing area per volume drastically falls. (dynamic drag and breaking losses)

Threading by pre-products

Depending on whether general purpose mechanosynthetic fabricators or mill style fabricators (serial chain of tools with no spaces) are used predominantly more or less layers and channels for threading parts by are needed [?].

Speed limit at the bottom

slow speed of assembly level 0: The mechanisms to assemble parts normally can potentially be smaller than the parts being assembled. Since The mechanisms to assemble minimal sized DMEs need themselves to be DMEs the mechanisms must have a similar size as the products they assemble. Since only a vew atoms are added per assembly step the density of actual building sites of atomic size is rather low and consequently mechanisms at the bottommost layers are quite a bit slower than the ones above and need to be included in greater numbers.

If assembly units of an assembly level produce (pre-)products slower than the size-characteristic frequency the next higher assembly level demands one can stack assembly units and thread by finished (pre-)products. Assembly units can be stacked as long as the size characteristic frequency of the threading by mechanics is not exceeded.

Ratios between levels

Layer and stage ratios: In any convergent assembly step a step size can be chosen. Big steps limit the maximum possible speed of the considered assembly level step but makes planning and programming more flexible and easier.

Influences of the branching factor

Branching factor: A branching factor of port area to block volume = n2/n3 leads to perfect size and frequency matching in an easy to design 3D iteration extruded 2D fractal design. Other ratios lead either to inefficient port space frequency and under used / under utilisized assembly levels or require 3D fractal designs that are more difficult to design. (There is no scale invariant design as baseline possible then)

Influences of assembly style

In any convergent assembly step one can choose from the different robotic manipulators to do the assembly. Mill style can (with the exception of the bottommost asselmbly level) have the smaller size and higher characteristic operation frequency of the lower assembly level. Single manipulator style assembly have the bigger size and smaller characteristic frequency of the upper assembly level. (Intermediate forms are possible). The choice depends on whether programmability or speed is the the primary concern.

More complicated geometries

non stratified 3D fractal designs need higher convergent assembly stages (assembly level IV) to hold the structure together. They have the highest possible performance (way above practically needed levels) other limits are likely to kick in at some point. Finding a general design methodology seems to be a hard problem.For physical changes of such a design a complete microcomponent disassembly end reassembly is likely necessary.

External links

Articles from E. Drexlers Blog:

- Complete molecular manufacturing systems will have many subsystems, designed to meet many constraints

- Physical scaling laws enable small machines to be highly productive

External references

- Nanosystems chapter 14