Gem-gum technology

The nature of products in this technology level is outlined in the definition of APM on the Main Page.

This page should give more details to the different aspects of advanced APM systems.

Defining traits of technology level III:

- robotic control (machine phase)

- handling of very small moieties or single atoms

- operation under vacuum

Navigation:

- start: technology level 0

- previous: technology level II

- pre-products: diamondoid metamaterials

- products: further improvement at technology level III

Productive nanosystems

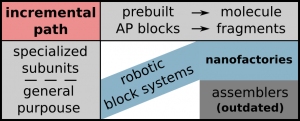

In the beginning of APM research only (molecular) assemblers where considered as a means for reaching the capability to produce macroscopic amounts of a product or block of material.

At T.Level III it turns out that advanced nanofactories are more balanced and efficient than assembler systems than at technology level I where the border between minimal assemblers and rudimentary nanofactories is more blurred. A rudimentary nanofactory might be buildabel with exponential assembly instead of self replication but simplified two dimensional assembler linkages/mechanisms might work too.

To have an umbrella term for both ideas The term productive nanosystems was introduced.

Using the whole volume for the building process of the product rather than a layer in the "classic" nanofactory design could speed up the building process. But this will not be necessary for practical usage [TODO find and link existing proof]. If you build a solid block though you might end up being slower than with the layer method due to the fractal growth speedup limit

Assembly levels

The assembly process of AP products can be clearly divided in a number of subsequent steps no matter whether the concrete implementation of a productive nanosytem looks more like a nanofactory or more like an assembler system. Those steps are implementation agnostic. Further details can be found on the assembly levels page.

Notes

- Depending on whether one assumes incremental improvement over technology levels or a more direct access there are two types of DME designs to choose from: pure hydrocarbon or various nonmetal including designs. Both have reason to be done.

- One may say that the concepts of nanofactories and assemblers are not entirely sharp seperable i.e. that they are merely the endpoints of a design continuum. To meet in the middle: The smallest possible grains of nanofactories (without the optional exponential assembly layers) somehow dispersed on a lattice in a volume could be looked at as a static configuration of quite big assemblers.

Assemblers

Note: The concept of assemblers is outdated!

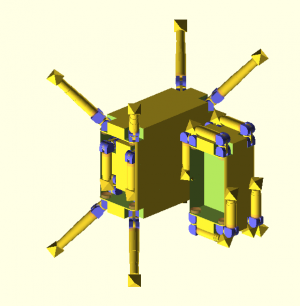

The idea is to create a machine with side-lengths of a few hundred nanometers which packages all the functionality to produce useful products and also make copies of itself (directly with diamondoid mechanosynthesis). This way you get an exponential rate of reproduction and can produce macroscopic goods in reasonable amounts of time.

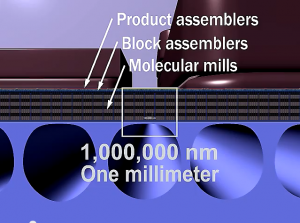

It turned out that packaging all the functionality into such a small package is a rather unbalanced and inefficient approach for T.Level III. This can be seen in the nanofactory cross section image (further down this page) where it is visible that the bottommost assembly levels (here layers) take the largest portion of the stack. In the small package of an assembler the bottommost layers would be underrepresented making it rather slow.

Quite a bit of thought was put into this model. Either they where supposed to swim about in a solution or there was some form of movement mechanism in a machine phase scaffold crystal envisioned like:

- sliding cubes [TODO add references]

- legged blocks [TODO add references]

The combination of their appearance (legs) with their very tightly packed capability of self replication in their vacuum "belly" that seem akin to a "whomb" led to the situation that the public started to perceive this technology as swarms of tiny life like nano-bugs that could potentially start uncontrollable and unstoppable self replication. Why this is a rather miss-informed opinion can be read up here.

Many considerations about assemblers are still relevant:

- methods for movement e.g. for the transport of microcomponents and self repair by microcomponent replacement in the higher assembly levels of nanofactories. The legged block mobility design is also known from the concept of (speculative) Utility Fog but has other design priorities in a manufacturing context like more rigidity and less "intelligence".

- methods for gas tight sealing

- and many more ...

- the design of robotic mechanosyntesis cores

Advanced nanofactories

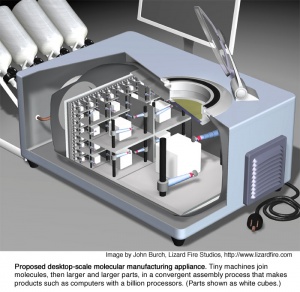

The attractive but distant aim point

How will a Nanofactory look like?

Lets start with the official productive nanosystem video.

If this looks like a fantasy to you be aware that this is a desired aim point and certainly not the first thing one wants to build from scratch.

Also beside the sorting and atom deposition which are already quite concrete the further up steps serve more as a conception of what goes where rather than a construction plan.

The blueish screen-shot on the right is from the video and shows all the assembly levels except IV. A strictly hight ordered stratified layout is presented.

What is shown in this video:

Correspondence to assembly levels:

- Assembly level 0 and I are grouped together and represented by the "molecular mills" step.

- Assembly level II is represented by the "block assemblers" step.

- Assembly level III is represented by the "product assemblers" step.

- Assembly level IV is not integrated since its optional.omitted All assembly levels except IV

- In the "molecular mills" step The notion of "next stage" marks the point from 0a to 0b (filtering and tooltip preparation).

- The tooltip preparation process is depicted simplified [todo: check in-how-far]. For the actually more complex preparations cycles the tooltips (with tipcones) for mechanosynthesis can be merged with carriage structures that can be steered by rail switches.

- The shown reaction which has been analyzed using "advanced quantum chemistry techniques" is not RS6. [Todo find out which it is supposed to be].

- Due to the assumption of limited to no steerability of the molecular mills a steerable routing system is needed. This routing system is conceptually shown between the "molecular mills" and the "block assemblers" step and in the video is called "transfer mechanism".

- Only mills are shown - a vew more flexible but slower robotic manipulators doing mechanosynthesis are likely augment them in a real system.

- The shown mill wheels could be extended to barrels. It is probably sensible to place more than just one atom per station. Some stripes of a whole layer maybe.

- The shown block and product assembler steps are rather wasteful of space and will probably look quite different in an actual design.

- Vacuum lock out is neither shown between "block" and "product assembler" step nor at the final macroscopic port. In a real system this must be integrated in at least one of these places.

The artistic depiction of a nanofactory depicted in the grayish image on the right only shows assembly level IV (higher convergent assembly). An iteration extruded 2D Fractal design is choosen.

More discussion of an advanced nanofactory design thats supposed to be an attractive but distant aim point.

To find out how a nanofactory will look like more accurately one must start with the systems internal sub-product logistics (mechanosynthesis and assembly) since:

Nanosystems 14.4.1 "... the details of supporting systems ... are peripheral to the central issues of molecular manufacturing ... ... a reasonable estimate of overall system volume can be be had by summing the volumes of the assembly workspaces without describing a particulate three-dimensional layout. ..."

When subsystem sizes are roughly known one can start to contemplate about the possible spacial configurations by making sure that production and consumption fits together at the borders between the assembly levels. This can be considered the level throughput balancing problem.

Its natural to think that it would be best to do mechanosynthesis in the whole nanofactories volume to get maximal productivity. That is to use dense construction style assembly without higher convergent assembly layers. Nanosystems ADDREF (known form early assembler system concepts). An estimation shows that running such a system at macroscopic speeds (which the DMME bearings can tolerate) leads to huge amounts of waste heat because of the high cumulative surface area of all the bearings. If one goes for maximum performance these levels of waste heat should be easily removable with AP pellet cooling systems. (other processing steps might limit assembly speed like e.g. molecule sorting [Todo: check]) The problems are that the high mass throughput would create unacceptably high acceleration forces and The product couldn't be easily removed from the construction scaffold especially at those high speeds.

A more living-room friendly design can be reached by either going down with the operating speed or doing mechanosynthesis and basic assembly only in a thin layer extruding the products out. This is called manufacturing style assembly higher convergent assembly hierarchy can be put on top and the base layer could be broken apart and distributed in this hirarchy.

Designs for the direct path

There is an interesting article about Nanofactory design written by Chris Phoenix in 2003 "Design of a Primitive Nanofactory". More information can be founds on the "discussion of proposed nanofactory designs" page.

Link: The Nanofactory Collaboration.

General

Note that in a stratified design that uses convergent assembly that is strictly ordered after assembly levels a block made from eight blocks must come from only four ports of the stage below. Consequently the production frequency must double with every stage one goes down, which is no problem since objects of half size can move with twice the frequency (a scaling law). (In computer terms you extract an octree out of a a quadtree). The lowest levels (assebly levels <= II) are significantly slower then the simple mergement steps above.

Filling a whole volume with the basic assembly levels keeping macroscopic speeds would lead to ridiculously high mass throughput and heat generation. Slowing down to mediocre waste heat still leaves high productivity. Using a thin well coolable layer is the classical nanofactory approach.

Design levels

APM systems can depending on the size of the chunk of them that is under considereration be designed at three different levels:

- tooltip chemistry level

- atomistic mechanic level

- lower bulk limit

- system level

Further details can de found on the design levels page.

Diamondoid Molecular Elements (DMEs)

At the core an advanced productive APM systems consist out of DMEs.

DMEs can be designed either directly at the atomistic level or in lower bulk limit form.

One can classify DMEs into:

- Diamondoid Molecular machine elements DMMEs

- Diamondoid Molecular structural elements DMSEs

Furthere details can be found diamondoid molecular elements page.

Certain standard sets like housing components or a minimal set of compatible DMMEs are needed.

Potential structural and machine elements that seem suitable to port them to DME designs can be found here:

- Thingiverse collection I

- [Todo: add further resources]

Depending on the design different degrees of modifications need to be done.

All degrees of freedome need to be controlled, wall thicknesses need to be increased, atomic roughness must be considered, ...

Logistics

A lot of media need to be shoved around in a nanofactory.

Included are: data; energy; raw material; heat; waste; partly finished products; vacua (in some sense); noble gasses

The use of electricity is avoided at the lowest size levels since tunneling and conduction around bents are nontrivial.

See non mechanical technology path.

The routing of the structures bearing those different media i.e. the schematics to physical layout mapping is part of the system level design. Some structures bearing the transmitted media can be found on the "diamondoid molecular elements" page.

Data processing

Computation must be done reversibly since deleting data dissipated energy. More about this can be found on the "reversible data processing" page. For AP electronic computer technology go to: non mechanical technology path

Vacuum

Mechanosynthesis of diamondoid materials in t.level III needs to be done in a "perfect" vacuum (or noble gas). Actually this is the defining trait seperating it from t.level II. Any free gas molecules would quickly react with the tooltips rendering them dysfunctional. From current perspective creation of "perfect" vacua seems illusionary. Any operator of an UHV system knows that it is impossible to get rid of all the gas molecules that are unavoidably adsorbed on the vacuuum vessels walls. The current perspective is based on the current technology though. The vacuum vessels for APM systems of t.level III

- are cavities sized in the nanometer range - this increases the probability of having zero gas molecules captured inside

- have atomically precise maximally flat walls - not allowing for gas adsorption and allowing for maximally tight seals without out-gassing lubricants

- can utilize atomically tight positive displacement pumps for vacuum generation - no backflow

and are thus capable of creating sufficient vacua. (About sealings and pumps: Nanosystems 11.4.2 & 11.4.3)

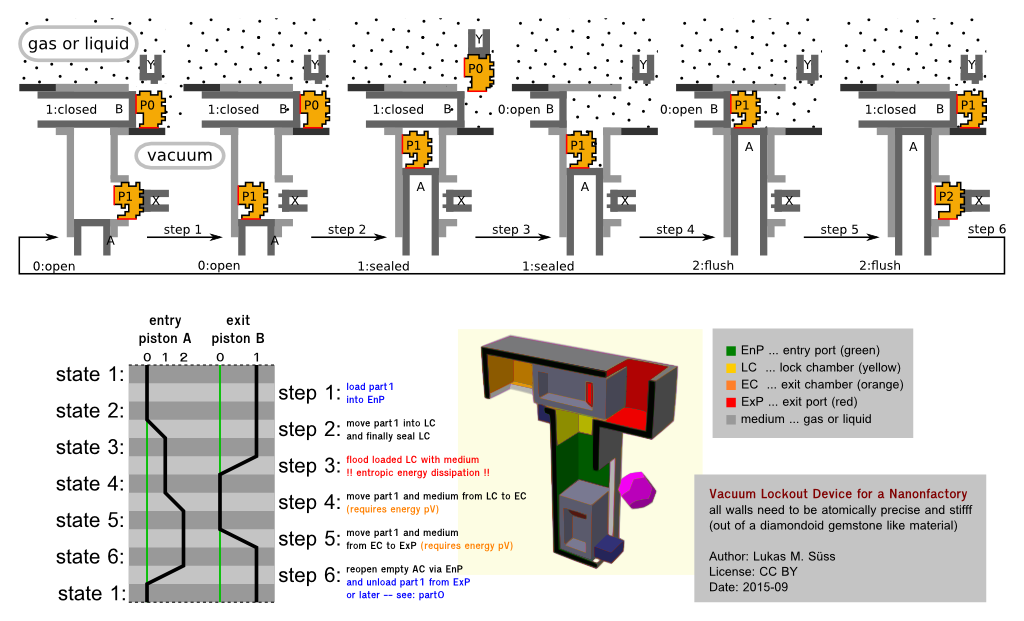

Locking out

At some place in the assembly levels (above Level II) products or fractions of them need to be locked out out of the vacuum area while keeping the interior perfectly gas free. This can be done with two pistons like depicted below. This method doubles as a pump for stray gas molecules. Import of parts (locking them in) is not possible here. Openings are wide enough to allow free molecular flow.

To get the parts through the airlock at some point one has to let go of the parts. To keep the parts in machine phase one can designed them to have three surfaces normal to each other at their outermost positions (red lines in graphic) so they stick in a corner by Van der Waals forces. Alternately for parts filling almost the whole chamber conical re-centering could be used to get the parts back into machine phase.

If not only dust free-ness but also vacuum is kept till the macroscopic outlet this waste free expulsion mechanism may not work because of wall bending & buckling at the macro scale [To inverstigate]. An other more wasteful proposal was to enclose the whole products in sausage shaped balloons (inflated by e.g. argon) which come one after another through a cylindrical output port and keep a tight seal at all times. This is more likely to work and can be designed without exposure of dangerous atomically sharp edges.

In an convergent assembly design if airlocks are installed at all assembly levels and the factory supports it it could be merged and split by hand. E.g. Take of the top stage and then split up the sub stages. A direct assembly design that supports it could be split at any perceivable ratio.

Locking in

It is more difficult to lock in parts. This reverse direction isn't a necessity for t.level III APM with its mechanosynthesis done in vacuum. A lot recycling can probably be done with passivated microcomponents in a non vacuum environment.

The ability to lock parts back in might be useful for tuning / repair / DME recycling on a sub microcomponent level (see assembly levels).

To get parts as clean as possible before locking them in again several measures can be taken:

- cleaning the un-disassembled product with very high pressure noble steams

- tag surface microcomponents as potentially dirt contaminated and scrap the hole shell (wasteful but better than scrapping the whole un-disassambled product)

- keep internals of porducts isolated (does not work if the product itself is a filter)

- filtering argon from air and blowing it outward in a pre-chamber forming a dust seal

To lock parts in by shearing off gas molecules is not an option since the parts can be arbitrarily shaped.

Still extremely low probabilities of remaining trapped gas molecules can be archived by usage of various pumping methods.

- using pistons / bellows that have a multiple volume of the handled parts

- operating pistons multiple times

- stacking airlocks in stages.

- additional usage of microscale turbo-molecular pumps (Nanosystems: Section 11.4.3.)

- exposed unpassivated surfaces

- slight heating if the nanofactory and product allows this (and when no remnants of temperature sensitive t.level I are included)

Examples for positive displacement pumps:

- piston pumps - advantage of high throughput area

- bellow pumps

- scroll pumps

- processing cavity pumps

alternate vacuum methods

- blowing up a vacuum bubble by either an extendable flexible skin or sliding blocks - Nanosystems: Figure 14.2. & Figure 14.3.

- extruding a cuboid out of a cuboid - this was an idea for assembler self replication - Nanosystems: Figure 14.6. & KSRM ...

- usage of some noble gas instead of vacuum to blow up non-stiff enclosures