Difference between revisions of "Molecular assembler (disambiguation)"

m (→Block placing assembler linkage: removed newline) |

|||

| Line 91: | Line 91: | ||

These are also relatively small and compact but they are incapable of [[mechanosynthesis]]. <br> | These are also relatively small and compact but they are incapable of [[mechanosynthesis]]. <br> | ||

More abstractly they have no manufacturing or demontage capabililities on the lowest [[assembly level]]. <br> | More abstractly they have no manufacturing or demontage capabililities on the lowest [[assembly level]]. <br> | ||

| − | Just like a [[microcomponent recomposer]]. <br> | + | Just like a [[microcomponent recomposer device]]. <br> |

| − | But a [[microcomponent recomposer]] is a macroscopic device whereas a [[microcomponent maintenance unit]] is a microscopic one. | + | But a [[microcomponent recomposer device]] is a macroscopic device whereas a [[microcomponent maintenance unit]] is a microscopic one. |

= Related = | = Related = | ||

Revision as of 11:15, 15 May 2021

Note: The concept of advanced molecular assemblers for diamondoid materials is outdated!

The current concept for advanced productive nanosystems of the "in-vacuum gem-gum technology" type are atomically precise small scale factories.

The three main problems with molecular assemblers are that they are:

- inefficient

- hard to reach

- undesirable

But molecular assemblers are:

- not fundamentally impossible

Molecular assemblers are member of the class of mobile naoscale robotic devices ("nanobots").

Molecular assemblers may emerge as products of advanced nanofactories (among other more useful "nanobots").

Contents

The idea

The idea is/was to create a machine with side-lengths of a few hundred nanometers which packages all the functionality to produce useful products and also make copies of itself (directly with diamondoid mechanosynthesis). This way you get an exponential rate of replication and can produce macroscopic goods in reasonable amounts of time.

Reasons for the problems

inefficiency:

It turned out that packaging all the functionality into such a small package is a rather unbalanced and inefficient approach for in-vacuum gem-gum technology. This can be seen in the nanofactory cross section image where it is visible that the bottommost assembly levels (there arranged as stacked coplanar layers) take the largest portion of the stack. In the small package of an assembler the bottommost layers would be highly underrepresented making it rather slow (and inefficient).

difficulty to reach:

See page: "Direct path".

reason for undesirability:

The grey goo horror fable toned waay down to realistic levels.

Still far down the road in the future (state 2017) and heavily limited by the requirements of the reproduction hexagon.

Assembler hype hiding progress to nanofactoies

The assembler concept was a natural and obvious bioanalogy to introduce initially. Continued refinement with exploratory engineering quickly led away from it though but this went almost unnoticed.

The combination of their appearance (legs or other mechanisms to move about) with their very tightly packed capability of self replication in their vacuum "belly" that seem akin to a "whomb" led to the situation that the public started to perceive this technology as swarms of tiny life like nano-bugs that could potentially start uncontrollable and unstoppable self replication.

Why this is a rather miss-informed opinion can be read up here and here.

- Dystopian SiFi fantasy anchored the idea of assemblers in the public perception (at least in USA and UK).

- Nanofactories coming close to the newer detailed concepts remain yet to be seen in fiction.

Partial design aspects of molecular assemblers that remain applicable

Many considerations about assemblers are still relevant:

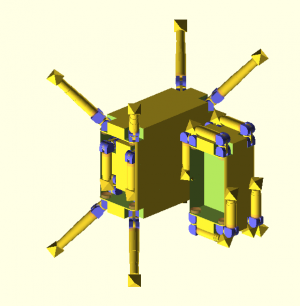

- methods for movement e.g. for the transport of microcomponents and self repair by microcomponent replacement in the higher assembly levels of nanofactories. The legged block mobility design is also known from the concept of (speculative) utility fog but has other design priorities in a manufacturing context like more rigidity and less "intelligence".

- methods for gas tight sealing and locking parts out

- and many more ...

- the design of robotic mechanosyntesis cores

Old assembler designs

Quite a bit of thought was put into the assembler model [Todo: link KSRM]. Either they where supposed to swim about in a solution or there was some form of movement mechanism in a machine phase scaffold crystal envisioned like:

- sliding cubes [TODO add references]

- legged blocks [TODO add references]

The ribosome and similar artificial biomimetic nano"machines"

These are also often called molecular assembler although they are:

- non self replication

- critically dependent on brownian movement

- and can only assembles floppy linear chain molecules which again need brownian motion to fold into something useful

Block placing assembler linkage

Unlike diamondoid assemblers this idea is not outdated. Atomically precise building blocks from structural DNA nanotechnology that are pre-produced by self assembly could be assembled to passive block manipulator linkages by those same passive block manipulator linkages after a first one was put together manually. Actuation could be from a chips surface (see technology level I) and self replication could work in the form of exponential assembly.

- Crystolecule assembly robotics might become capable of more or less compact self replication with predelivered "vitamin" pasts from the mechanosynthesis cores.

- Wikipedia: Clanking replicator. A term to distinguish macroscale selfreplication from nanoscale selfreplication. But crystolecule level self replication is very similar to macroscale self replication. So the meaning can be dragged back. A clanking nano replicator so to say. (Sidenote: actual clanking "sounds" should be avoided. Sound emission = loss of energy = inefficient operation = need for waste heat removal)

Possible exceptions where somewhat molecular assemblers like designs may not yet be completely outdated

The only place where the slow and inefficient molecular assembler concept may be practically usable is for

self repair situations where the demand on product throughput rate is exceptionally low.

Like fixing low rates of damage from natural background radiation.

See: Self repairing system#In place self-repair

But even there a multi part system is more practical and likely.

So it wold not operate alone but rather in conjunction with microcomponent maintenance units.

Microcomponent mainenance units ≠ Molecular assemblers

Main page: Microcomponent maintenance unit

Molecular assemblers are not to confuse with microcomponent maintenance units.

These are also relatively small and compact but they are incapable of mechanosynthesis.

More abstractly they have no manufacturing or demontage capabililities on the lowest assembly level.

Just like a microcomponent recomposer device.

But a microcomponent recomposer device is a macroscopic device whereas a microcomponent maintenance unit is a microscopic one.

Related

- Mobile robotic device

- Fractal growth speedup limit

- In place assembly and in place mechanosynthesis

(wiki-TODO: add image of dividing cells illustrating the analogy - use it on other related pages too - goo)