Difference between revisions of "Positional assembly redundancy blockade"

(→Relation of the "positional assembly blockade" to various development path approaches: improved section == Bottom up positional assembly == massively) |

m (→Bottom up positional assembly) |

||

| Line 82: | Line 82: | ||

If we manage to self assemble a system capable of positionally assemblying the same system, <br> | If we manage to self assemble a system capable of positionally assemblying the same system, <br> | ||

what is the point in positionally assembling the system then? <br> | what is the point in positionally assembling the system then? <br> | ||

| − | So while eventually becoming possible likely of limited use. <br> | + | So while eventually becoming possible, such capabilities likely will be of limited use. <br> |

Except farther out maybe. See [[Mechanosynthesis of biodegradables]] and ... | Except farther out maybe. See [[Mechanosynthesis of biodegradables]] and ... | ||

Revision as of 12:22, 17 September 2022

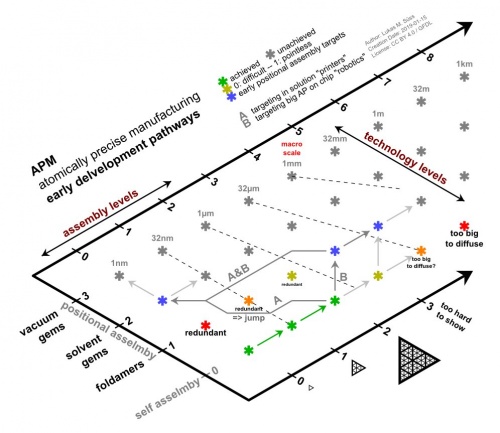

It would be nice if we could go to more advanced materials as soon as possible.

Climbing the technology levels as soon as possible that is.

Straight along the left axis if the diagram.

But there is an obstruction.

The "Positional assembly redundancy blockade".

Stars marked with "redundant".

Contents

Relation to pathways

Direct path - no such blockade

One of course can try the direct path, which has it's severe challenges.

But also it has it's merits since there is no other way to create such advanced material right away other than positional assembly. The direct path leapfrogs the "positional assembly redundancy blockade"

Incremental path - the bockade is present

Within the incremental path there is a "positional assembly redundancy blockade" though. Meaning an specific sub-area in the space of possible technological evolutions where all what positional assembly could do can be done with self assembly just as easy if not much easier.

Q: When is one running into the positional assembly redundancy blockade?

A: When trying to do positional assembly right away with still small pre-self-assembled / pre-self-folded building blocks.

Q: Why is one running into the positional assembly redundancy blockade then?

A: Because such small pre-selfassembled stuctures are well capable of encoding their target position in their own surface structure. As such all assembly that can be done with positional assembly can be done with self-assembly too. Just easier.

Q: So what's the advantage of positional assembly then?

A: The main reason we want to go for positional assembly so hard is that there are higher performance materials (gemstones and small stiff molecule building blocks) that just simply cannot encode the target position of their constitute parts in the the surface of their constitute parts since the surface is too small.

In the extreme: One cannot carve the "surface of an atom" to be shape complementary to an other atom.

All atoms of the same element are exactly identical and indistinguishable.

Overlooking isotopes which is irrelevant for chemical surface properties.

Relation of the "positional assembly blockade" to various development path approaches

(wiki-TODO: review this section - feels like there are some mix-ups in there)

Bottom up positional assembly

Note the recurring pattern:

Scale self-assembly some more till some sort of positional assembly becomes possible that

can do something that self assembly absolutely cannot do or has a very hard time with.

The robo approach:

By not switching to positional assembly till

– selfassembly skills are scaled up quite a lot and thus

– thermally driven self-assembly no longer works well since parts become too big

it evades the redundancy blockade the most, making a really wide detour around the blockade.

The printer approach:

By not switching to positional assembly till

– 3DOF bottom up positional assembly becomes reasonably possible and thus

– non-selfassemblable superior materials become accessible as the target for this positional assembly

it evades the blockade too, but more minimalistically than the robo approach.

The catalysis construction kit approach:

– If there is some allosteric programmability or

– if there is some energy transfer via mechanical motion from fuel molecules to reaction sites (disputed)

then (stretching it quite a bit) one could consider this a smallest possible seed of bottom up positional assembly. (Related: Kinematic loop)

Especially if ribosome like chain molecule synthesis capabilities become present.

While larger blocks may be modular and composable,

functionality carried by the block for smaller scale catalysis is not necessarily so.

Basically the infamous fat finger problem applies here.

By attempting to right away switch to positional assembly of non-selfassemblable superior materials

(catalysis of catabolic/constructive bond forming reactions) one cannot expect much more capability than that.

Generally:

Bottom up positional assembly of non-self assemblable materials just does not really work well as long as

self assembly capabilities have not been scaled up sufficciently. One runs into the the infamous fat finger problem.

Bottom up positional assembly of self-assemblable materials is redundant with the very same means of self-assembly of these materials. That is:

If we manage to self assemble a system capable of positionally assemblying the same system,

what is the point in positionally assembling the system then?

So while eventually becoming possible, such capabilities likely will be of limited use.

Except farther out maybe. See Mechanosynthesis of biodegradables and ...

Top down positional assembly

- The robo approach from the other side, again evading the blockade by wide margin. MEMS gripper manipulation of very very big self-assemblies.

- Trying to assemble sturdier kinds of foldamers (like e.g. de-novo proteins) by means of scanning probe microscopy. This runs quite hard into the barrier. There are some similarities in directness to the direct path. While maybe easoer then the direct path, there should still be way easier methods using further scaling of self-assembly.

- The direct path. As mentioned this would entirely leapfrog the barrier.