Thermal isolation

Thermal isolation in technology level III is problematic when one restricts oneself to pure hydrocarbon systems. Diamond is the worst possible thermal isolator. More generally the allotropes of carbon (diamond, lonsdaleite, graphene, nanotubes, fullerenes?) are all pretty bad thermal isolators.

Structuring carbon in novel ways may yield acceptable results. Regular gaps between electrically conductive surfaces can have influence on the allowed modes of electromagnetic (heat) radiation transport. (Todo: check whether macroscopic structures can be electro-statically levitated in multiple shells whith nano-scale distances in between)

If the incremental path was taken silicates may me mechanosynthesizable to an AP aerogel like substance.

A lack of material stiffness may pose problems.

The stiff structures desirable for AP systems somewhat contradict low thermal conductance since they usually lead to a high phononic (lattice vibration) contribution to thermal conductance. Electronic contributions can be kept low more easily.

Because of the scaling laws for surface-to-volume-ratio single isolated nanoscale parts would cool of / heat up instantly to average environment temperature. Thus Thermal isolation makes only sense in makroscopically divided spaces.

[Todo: Check out which effect the use of tensegrity structures has on thermal isolation.]

Thermal conduction adjustment µ-components

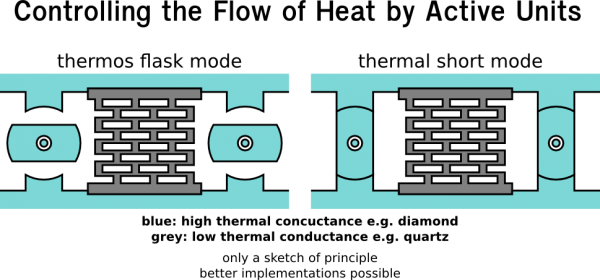

A metamaterial for practically instant adjustment of thermal conduction can be made from components that are optimized for thermal isolation but can be actuated such that a stiff diamond bridge is made that creates a thermal short circuit. Such materials would be perfect for advanced atomically precise produced clothing.

The diamond thermal bridge coupling needs to be stiffly clamped in all three dimensions for maximal thermal conductance thus it may be better to make the individual bridges bridge binary in action (either off or on) instead of continuously sliding together (which may leave one dimension less stiff coupled. The global thermal conductance can still be adjusted by the number and location of activated thermal bridges.

A sliding design would only be necessary for keeping nano-scale thermal differences. Such differences are very short lived even with the best possible thermal isolation since the surface to volume ratio of nano scale heat spots is so big and thus their little heat capacity is quickly depleted.

Isotopic enrichment of the carbon atoms in the thermal bridges can further increase thermal conductance. The shape of the thermal bridges can be optimized (smooth?) to not disturb the phonons. Or they can be made in wedge shape adding a thermal diode effect - an anisotropic heat conductance like presented here: [Todo: add link]

[Todo: include illustrating image]

A slightly different method would be the use of highly heat conductive coplanar sheets that can be separated or brought in (interlocking) contact with some kind of barely heat conducting scissoring mechanism. This Metamaterial would change its volume when it changes its heat conductivity. Also if it increases it's volume in an atmosphere its pulling up a vacuum thus quite a bit of energy needs to be put in. When the volume gets decreased the energy can get recuperated. Although it works with air pressure nothing of the energy that is put in will be converted to a temperature difference like in entropomechanical converters since the outer pressure stays constant.