Difference between revisions of "Foldamer technology stiffness nesting"

(basic page - likely still many errors) |

(some reordering and cleanup) |

||

| Line 1: | Line 1: | ||

{{stub}} | {{stub}} | ||

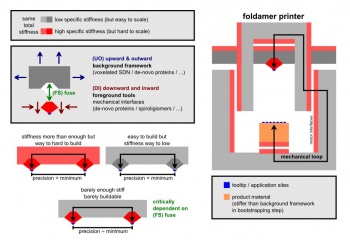

[[File:Foldeamer-printer-stiffness-adapters.jpg|thumb|right|350px|'''Left:''' Adding small inserts that can be made stiffer in a lower stiffness background framework that can be made bigger. '''Right:''' Application of such a combining of self-assembly technologies technology demonstrated in the context of the [[foldamer printer]] concept.]] | [[File:Foldeamer-printer-stiffness-adapters.jpg|thumb|right|350px|'''Left:''' Adding small inserts that can be made stiffer in a lower stiffness background framework that can be made bigger. '''Right:''' Application of such a combining of self-assembly technologies technology demonstrated in the context of the [[foldamer printer]] concept.]] | ||

| + | |||

| + | '''The idea here is to combine the different foldamer technologies to get the best of all the worlds.''' <br> | ||

| + | |||

There are various forms of [[foldamer technology]] under development. <br> | There are various forms of [[foldamer technology]] under development. <br> | ||

| Line 7: | Line 10: | ||

– … the least scalable technologies feature the most stiffness <br> | – … the least scalable technologies feature the most stiffness <br> | ||

| − | + | Very importantly: <br> | |

| − | + | '''Scalability here does not mean mere quantity but only the quantity for which full [[termination control]] can be achieved.''' | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | == Technologies form least stiff most scalable to most stiff least scalable == | |

| − | + | ||

| − | + | * [[3D structural DNA nanotechnology]] - all mere [[topological atomic precision]] | |

| − | + | * [[de-novo proteins]] - [[positional atomic precision]] not so floppy side-chains => oringin of [[fat fingers]] | |

| − | + | * [[spiroligomers]] and stiff artificial sidechains - [[positional atomic precision]] | |

| + | * small core [[crystolecules]] - if direct path gets so far on it's own - [[positional atomic precision]] | ||

| + | |||

| + | Side-note on scalability: <br> | ||

| + | Spiroligomers may be scalable in the quantity of them synthesizable. <br> | ||

| + | Here we look at scalability in therms of selfassembly with [[termination control]] though. <br> | ||

| + | |||

| + | == Combining of technologies to get max scalability and max stiffness where they matter == | ||

| − | The | + | The bigger-than-inter-atom-spacing-thermal-wiggles of a 3D structural DNA nanotechnology background framework <br> |

| − | + | that features merely [[topological atomic precision]] <br> | |

| − | + | may eventually even statistically cancel out to give [[positional atomic precision]] <br> | |

| − | Though | + | of the nested stiffer de-novo protein core and <br> |

| + | of the further nested stiff artificial side-chains on that protein. <br> | ||

| + | Though achieving a wiggle-reduction all the way down to [[positional atomic precision]] in one swoop is not strictly necessary | ||

| + | to get to a next gen better material techology enabled by semi-positional assembly. <br> | ||

It's much more likely that things will evolve more gradually. <br> | It's much more likely that things will evolve more gradually. <br> | ||

Maybe this idea is more to treat conceptually. <br> | Maybe this idea is more to treat conceptually. <br> | ||

| + | Same in other words: [[Positional atomic precision]] (or near that) is only eventually needed between the workpiece and the tool-tip. <br> | ||

| + | There is no need for [[positional atomic precision]] in the much larger "background framework/spacefame". <br> | ||

| + | The background framework merely feature [[topological atomic precision]]. <br> | ||

| + | Even with quite a bit of tolerable errors. | ||

| + | |||

| + | A protein core in a 3D structural DNA background framework matrix features a stiffness not defined solely by the elastic moduli, <br> | ||

| + | but rather by the interface surface area too. This area needs to be factored in to get the total stiffness. | ||

| + | |||

| + | The conceptual math trick here is to look at absolute stiffnesses in N/m <br> | ||

| + | rather than area specific stiffnesses in (N/m)/m² i.e. elastic modulus. <br> | ||

| + | Then look at the chain that forms parts or the whole of a [[kinematic loop]]. | ||

| + | |||

== The incurred challenge == | == The incurred challenge == | ||

| Line 35: | Line 56: | ||

Beside the huge experimental problems with that there's also not much software around for that (as of mid 2024). <br> | Beside the huge experimental problems with that there's also not much software around for that (as of mid 2024). <br> | ||

The MSEP project has a focus on that cross technology mergability / connectability. <br> | The MSEP project has a focus on that cross technology mergability / connectability. <br> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Alternate names == | == Alternate names == | ||

Revision as of 10:44, 17 June 2024

The idea here is to combine the different foldamer technologies to get the best of all the worlds.

There are various forms of foldamer technology under development.

A pattern that one may spot here is that …

– … the most scalable technologies feature the least stiffness while

– … the least scalable technologies feature the most stiffness

Very importantly:

Scalability here does not mean mere quantity but only the quantity for which full termination control can be achieved.

Contents

Technologies form least stiff most scalable to most stiff least scalable

- 3D structural DNA nanotechnology - all mere topological atomic precision

- de-novo proteins - positional atomic precision not so floppy side-chains => oringin of fat fingers

- spiroligomers and stiff artificial sidechains - positional atomic precision

- small core crystolecules - if direct path gets so far on it's own - positional atomic precision

Side-note on scalability:

Spiroligomers may be scalable in the quantity of them synthesizable.

Here we look at scalability in therms of selfassembly with termination control though.

Combining of technologies to get max scalability and max stiffness where they matter

The bigger-than-inter-atom-spacing-thermal-wiggles of a 3D structural DNA nanotechnology background framework

that features merely topological atomic precision

may eventually even statistically cancel out to give positional atomic precision

of the nested stiffer de-novo protein core and

of the further nested stiff artificial side-chains on that protein.

Though achieving a wiggle-reduction all the way down to positional atomic precision in one swoop is not strictly necessary

to get to a next gen better material techology enabled by semi-positional assembly.

It's much more likely that things will evolve more gradually.

Maybe this idea is more to treat conceptually.

Same in other words: Positional atomic precision (or near that) is only eventually needed between the workpiece and the tool-tip.

There is no need for positional atomic precision in the much larger "background framework/spacefame".

The background framework merely feature topological atomic precision.

Even with quite a bit of tolerable errors.

A protein core in a 3D structural DNA background framework matrix features a stiffness not defined solely by the elastic moduli,

but rather by the interface surface area too. This area needs to be factored in to get the total stiffness.

The conceptual math trick here is to look at absolute stiffnesses in N/m

rather than area specific stiffnesses in (N/m)/m² i.e. elastic modulus.

Then look at the chain that forms parts or the whole of a kinematic loop.

The incurred challenge

The various different kinds of technologies need to me made compatible in the sence of connectability.

The formable connections need to feature a stiffness that is not notably lower than the stiffness of the

less stiff technology of the pair to connect.

Beside the huge experimental problems with that there's also not much software around for that (as of mid 2024).

The MSEP project has a focus on that cross technology mergability / connectability.

Alternate names

- Matryoshka doll stiffness nesting

- Onyon stiffness nesting