Difference between revisions of "Gemstone-like molecular element"

m (→VdW sticking) |

(→Base material: added links to assembly levels) |

||

| (102 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

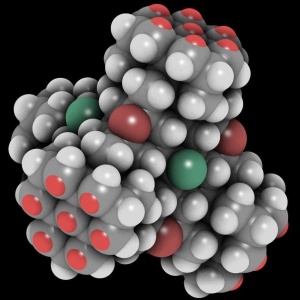

| − | + | [[File:Tetrapod-openconnects display large square.jpg|300px|thumb|right|Here is a rather small structural [[diamondoid]] [[crystolecule]] with some bonds (brighter red) intentionally left [[Nanoscale surface passivation|open/dangling/unpassivated]]. A [[crystolecule fragment]]. Such [[surface interface]]s can be fused together via [[seamless covalent welding]] in the [[second assembly level]] and perhaps higher assembly levels.]] | |

| − | + | ||

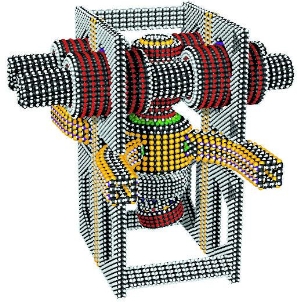

| − | + | [[File:atomistic acetylene sorting pump model.jpg|frame|A proposed [[acetylene sorting pump]]. This is a larger [[diamondoid machine element]] (DME). Possibly assembled from several pre-produced smaller [[diamondoid crystolecule]]s. The frame is one big monolithic crystolecule (it may be fused togehter via [[seamless covalent welding]] during assembly). Other parts are smaller independent crystolecules that may be [[piezochemical mechanosynthesis|mechanosynthesized]] fully passivated as a whole and integrated as a whole without any seamless welding.]] | |

| − | + | ||

| − | ''' | + | '''Gemstone-like molecular elements''' (GMEs) here also called '''crystolecules''' are parts of machine elements and structural elements at the lowermost physical size limit. |

| + | They are produced via [[piezochemical mechanosynthesis]] and are often highly symmetrical. | ||

| + | Gemstone-like molecular elements are the basic building blocks in [[gemstone metamaterial technology]]. | ||

| − | + | = Base material = | |

| − | + | ||

| − | + | ||

| − | + | [[Gemstone-like compounds]] are the most suitable base material for crystolecules. | |

| + | Beside classical gemstones like diamond other semi-precious minerals including bio-minerals that are synthesizable in solution also fall under gemstone-like compounds. | ||

| + | These may be accessible earlier in [[technology level II|semi advanced]] precursor technologies. | ||

| − | + | Use of [[pure metals and metal alloys]] is rather unsuitable for crystolecules. | |

| + | * Metallic bonds with free electron gas are not directed like covalent bonds. | ||

| + | * Metal atoms on metal surfaces tend to [//en.wikipedia.org/wiki/Surface_diffusion diffuse] away from where they have been deposited. Especially on surfaces. | ||

| − | + | Crystolecules are: | |

| + | * assembled from small [[molecule fragments]] – in the [[Assembly level 1 (gem-gum factory)|first assembly level]] – typically mostly irreversible | ||

| + | * assembled to bigger [[crystolecular unit]]s – in the [[Assembly level 2 (gem-gum factory)|second assembly level]] – typically partially irreversible | ||

| − | + | '''Given their nanoscale gemstone like nature unfortunately crystolecules and their assemblies [[crystollecular element|crystollecular (machine) elements]] cannot be produced yet (state 2015..2021).''' | |

| − | + | A subclass of [[gemstone-like compounds]] are [[diamond like compounds]]. (For a disambiguation see: [[Diamondoid]]) <br> | |

| + | Accordingly a subclass of [[gemstone-like molecular element]]s are [[diamondoid molecular element]]s. | ||

| + | * '''[[Diamondoid molecular machine element]]s''' (DMMEs) are assemblies of some diamondoid crystolecules implementing one specific mechanical function | ||

| + | * '''[[Diamondoid molecular structural element]]s''' (DMSEs) are crystolecules or assemblies of some diamondoid crystolecules implementing a structural function | ||

| − | + | = Beware of the stroboscopic illusion = | |

| − | + | {| class="wikitable floatright" style="margin-left: auto; margin-right: 0px;" | |

| + | |- | ||

| + | |'''well animated bearing''' <br> The fast thermal vibrations are more realistically blurred out. The remaining localized periodic average deformations (visible here if one looks closely) are highly reversible. (See page abbout "[[superlubrication]]".) | ||

| + | |'''badly animated bearing''' <br> The present stroboscopic effect can be misleading in that friction is likely to be grossly overestimated. It deceivingly looks like as if the operating speed would be close to the speed of the thermal vibration. If that where the case it indeed would cause massive friction (strong coupling of motions with similar frequency). | ||

| + | |- | ||

| + | | [[File:SmallBearingSmoothAnimation.gif|right|DMME - bearing with blurred out fast vibrations]] | ||

| + | |[[File:SmallBearingStrobeAnimation.gif|right|DMME - bearing with misleading stroboscopic effect]] | ||

| + | |} | ||

| − | + | '''Simulated DMEs often show a misleading stroboscopic effect''' which can make one believe that the operation frequencies lie near the thermal frequencies, giving the false impression of enormously high friction but actually the contrary is true. <br> | |

| + | See: "[[Friction in gem-gum technology]]" and "[[Superlubrication]]". | ||

| − | + | Gemstone like molecular machine elements with sliding interfaces will work exceptionally well. (See: [[Superlubricity]]) <br> | |

| + | There is both experimental evidence and theoretical evidence for that. <br> | ||

| + | (See e.g.: [[Evaluating the Friction of Rotary Joints in Molecular Machines (paper)]] and the friction analysis in [[Nanosystems]]) | ||

| − | = | + | = Nomenclature = |

| − | + | Since the here described physical objects have no official name yet (2016..2021) <br> | |

| − | + | something sensible must be invented to refer to them in this wiki. | |

| − | + | ||

| − | = | + | = "Crystolecules" – Term introduction and definition = |

| − | + | These objects are somewhat of a cross between a crystal and a molecule. <br> | |

| − | + | So let's use the term '''"crystolecule"'''. <br> | |

| − | + | This is nice because it's: | |

| − | + | * quite accurate in descriptiveness | |

| − | + | * quite conveniently usable in natural language | |

| + | * quite memorably (catchy) because it seems unusual (clickbait effect) | ||

| − | + | Specificall lets use the term "crystolecule" for ones that are typically are: | |

| − | + | * small – stiff – minimal | |

| − | + | * structural | |

| + | * monolithic (like illustrated) | ||

| + | * do (typically) not yet feature irreversibly enclosed moving parts – (no [[form closure]] yet – there may be exceptions) | ||

| + | * are assembled purely at the first assembly level by [[piezochemical mechanosynthesis]] (direct [[in place assembly]]) | ||

| − | + | = Crystolecular units = | |

| − | + | '''See main page: [[Crystolecular unit]]''' | |

| − | + | These are bigger assemblies of basic structural crystolecules. <br> | |

| − | + | Assembled from crystolecules either via [[seamless covalent welding]] or [[Van der Waals force sticking]] and/or [[shape closing interlocking]] | |

| − | + | Let's use a different name for crystolecules or assemblies of crystolecules that are typically: | |

| + | * a bit bigger | ||

| + | * also functional in nature not just structural | ||

| + | * not monolithic | ||

| + | * do feature irreversibly enclosed moving parts | ||

| + | * may involve pick and place post assembly (from constituent crystolecules) at the next higher assembly level | ||

| − | [ | + | Generally crystolecules and [[crystolecular unit]]s will be made from [[gemstone like compound]]s. <br> |

| + | One subclass already investigated a bit in molecular detail are the [[crystolecular unit]]s made from [[diamondoid like compound]]. | ||

| + | Specifically some ones made from [[diamond]] and [[moissanite]] where investigated. | ||

| + | See: '''[[Examples of diamondoid molecular machine elements]].''' | ||

| − | == | + | == Diamondoid molecular (structural and machine) elements – Term introduction and definition == |

| − | + | Let's use: | |

| + | * Diamondoid molecular structural elements (DM'''S'''Es) for structural ones of all sizes including beside small ones also bigger ones | ||

| + | * Diamondoid molecular machine elements (DM'''M'''Es) for functional ones that are typically bigger in size | ||

| + | * Diamondoid molecular elements (DMEs) for structures of all sized including both of the former | ||

| + | * ("Diamondoid" can be replaced by "Gemoid" to include more general gemstone like compounds like e.g. [[sapphire]]) | ||

| − | + | Examples: | |

| − | + | * On this wiki: [[Examples of diamondoid molecular machine elements]] | |

| − | ''' | + | * (DM'''M'''Es) ([http://www.zyvex.com/nanotech/visuals.html examples]) like e.g. bearings and gears have completely passivated surfaces. |

| + | * (DM'''S'''Es) ([http://www.thingiverse.com/thing:13786 example]) these are typically only partially passivated. They can expose multiple radicals on some of their surfaces that act as [[positional atomic precision|AP]] [[surface interfaces|welding interfaces]] to complementary surfaces. The assembly step of connecting [[surface interfaces]] is here called "[[seamless covalent welding]]" and is done in the next higher assembly level ([[assembly levels|assembly level II]]?). [[Seamless covalent welding]] it usually is irreversible but sparsely linking versions may be reversible. | ||

| − | + | == Delineation – what crystolecules must not be confused with == | |

| − | + | ||

| − | + | ||

| − | + | Crystolecules must not be confused with crystals out of folded up polypeptide molecules aka proteins (that are made today to find the locations of their constituent atoms). <br>To emphasize the distinction one could use the term "covalent crystolecules". | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | = Related = | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | ''' | + | * '''[[Terminology for parts]]''' |

| − | + | * For components at different size scales see: [[Components]] | |

| − | + | * [[Stroboscopic illusion in crystolecule animations]] | |

| − | + | * [[Example crystolecules]] | |

| − | [[ | + | * [[nanoparticle]]s |

| − | + | * [[In place assembly]] | |

| − | + | * putting molecule-fragments together to crystolecules [[Mechanosynthesis core]] | |

| − | + | * putting crystolecules together to microcomponents [[Crystolecule assembly robotics]] | |

| − | * | + | ----- |

| − | + | * [[Mechanical circuit element]]s | |

| − | + | ----- | |

| − | + | Terms for bigger assemblies of several [[crystolecules]] but not yet as big (and disassemblable) as [[microcomponents]] | |

| − | + | * [[Diamondoid crystolecular machine element]] – diamond like structure – See: [[Diamondoid]] | |

| − | * | + | * [[Crystolecular machine element]] – more general gemstone like structure – See: [[gemstone like compound]] |

| − | + | ----- | |

| − | + | * assembled from [[molecule fragments]] | |

| − | + | * assembled to [[crystolecular element]]s | |

| − | + | * assembly is typically irreversible | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | * | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | [ | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | [ | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | [ | + | |

= External links = | = External links = | ||

| + | At K. Eric Drexlers website: | ||

| + | * [http://e-drexler.com/p/04/02/0315bearingDiag.html A shaft in a sleeve can form a rotary bearing] | ||

| + | * [http://e-drexler.com/p/04/03/0323bearingDesigns.html Sleeve bearings have been designed and modeled in atomic detail] (here shown minus the stroboscopic illusion) | ||

| + | ---- | ||

| + | * [//en.wikipedia.org/wiki/Structural_element structural elements] | ||

| + | * [//en.wikipedia.org/wiki/Machine_element machine elements] | ||

* [http://www.iberchip.net/iberchip2006/ponencias/86.pdf Design of Nanomachines using NanoEngineer-1] | * [http://www.iberchip.net/iberchip2006/ponencias/86.pdf Design of Nanomachines using NanoEngineer-1] | ||

| + | * "Nanomachines: How the Videos Lie to Scientists" [https://web.archive.org/web/20160322114752/http://metamodern.com/2009/02/10/nanomachines-how-the-videos-lie-to-scientists/ (archive)] [http://metamodern.com/2009/02/10/nanomachines-how-the-videos-lie-to-scientists/ (old dead link)] | ||

| + | * without stroboscopic illusion: [https://www.youtube.com/watch?v=RosHyQUw5jI Molecular dynamics simulation of small bearing design] | ||

| + | * [http://www.somewhereville.com/?p=82 A Low-Friction Molecular Bearing Assembly Tutorial, v1] | ||

| + | |||

| + | [[Category:Technology level III]] | ||

Latest revision as of 07:38, 3 July 2022

Gemstone-like molecular elements (GMEs) here also called crystolecules are parts of machine elements and structural elements at the lowermost physical size limit. They are produced via piezochemical mechanosynthesis and are often highly symmetrical. Gemstone-like molecular elements are the basic building blocks in gemstone metamaterial technology.

Contents

Base material

Gemstone-like compounds are the most suitable base material for crystolecules. Beside classical gemstones like diamond other semi-precious minerals including bio-minerals that are synthesizable in solution also fall under gemstone-like compounds. These may be accessible earlier in semi advanced precursor technologies.

Use of pure metals and metal alloys is rather unsuitable for crystolecules.

- Metallic bonds with free electron gas are not directed like covalent bonds.

- Metal atoms on metal surfaces tend to diffuse away from where they have been deposited. Especially on surfaces.

Crystolecules are:

- assembled from small molecule fragments – in the first assembly level – typically mostly irreversible

- assembled to bigger crystolecular units – in the second assembly level – typically partially irreversible

Given their nanoscale gemstone like nature unfortunately crystolecules and their assemblies crystollecular (machine) elements cannot be produced yet (state 2015..2021).

A subclass of gemstone-like compounds are diamond like compounds. (For a disambiguation see: Diamondoid)

Accordingly a subclass of gemstone-like molecular elements are diamondoid molecular elements.

- Diamondoid molecular machine elements (DMMEs) are assemblies of some diamondoid crystolecules implementing one specific mechanical function

- Diamondoid molecular structural elements (DMSEs) are crystolecules or assemblies of some diamondoid crystolecules implementing a structural function

Beware of the stroboscopic illusion

| well animated bearing The fast thermal vibrations are more realistically blurred out. The remaining localized periodic average deformations (visible here if one looks closely) are highly reversible. (See page abbout "superlubrication".) |

badly animated bearing The present stroboscopic effect can be misleading in that friction is likely to be grossly overestimated. It deceivingly looks like as if the operating speed would be close to the speed of the thermal vibration. If that where the case it indeed would cause massive friction (strong coupling of motions with similar frequency). |

Simulated DMEs often show a misleading stroboscopic effect which can make one believe that the operation frequencies lie near the thermal frequencies, giving the false impression of enormously high friction but actually the contrary is true.

See: "Friction in gem-gum technology" and "Superlubrication".

Gemstone like molecular machine elements with sliding interfaces will work exceptionally well. (See: Superlubricity)

There is both experimental evidence and theoretical evidence for that.

(See e.g.: Evaluating the Friction of Rotary Joints in Molecular Machines (paper) and the friction analysis in Nanosystems)

Nomenclature

Since the here described physical objects have no official name yet (2016..2021)

something sensible must be invented to refer to them in this wiki.

"Crystolecules" – Term introduction and definition

These objects are somewhat of a cross between a crystal and a molecule.

So let's use the term "crystolecule".

This is nice because it's:

- quite accurate in descriptiveness

- quite conveniently usable in natural language

- quite memorably (catchy) because it seems unusual (clickbait effect)

Specificall lets use the term "crystolecule" for ones that are typically are:

- small – stiff – minimal

- structural

- monolithic (like illustrated)

- do (typically) not yet feature irreversibly enclosed moving parts – (no form closure yet – there may be exceptions)

- are assembled purely at the first assembly level by piezochemical mechanosynthesis (direct in place assembly)

Crystolecular units

See main page: Crystolecular unit

These are bigger assemblies of basic structural crystolecules.

Assembled from crystolecules either via seamless covalent welding or Van der Waals force sticking and/or shape closing interlocking

Let's use a different name for crystolecules or assemblies of crystolecules that are typically:

- a bit bigger

- also functional in nature not just structural

- not monolithic

- do feature irreversibly enclosed moving parts

- may involve pick and place post assembly (from constituent crystolecules) at the next higher assembly level

Generally crystolecules and crystolecular units will be made from gemstone like compounds.

One subclass already investigated a bit in molecular detail are the crystolecular units made from diamondoid like compound.

Specifically some ones made from diamond and moissanite where investigated.

See: Examples of diamondoid molecular machine elements.

Diamondoid molecular (structural and machine) elements – Term introduction and definition

Let's use:

- Diamondoid molecular structural elements (DMSEs) for structural ones of all sizes including beside small ones also bigger ones

- Diamondoid molecular machine elements (DMMEs) for functional ones that are typically bigger in size

- Diamondoid molecular elements (DMEs) for structures of all sized including both of the former

- ("Diamondoid" can be replaced by "Gemoid" to include more general gemstone like compounds like e.g. sapphire)

Examples:

- On this wiki: Examples of diamondoid molecular machine elements

- (DMMEs) (examples) like e.g. bearings and gears have completely passivated surfaces.

- (DMSEs) (example) these are typically only partially passivated. They can expose multiple radicals on some of their surfaces that act as AP welding interfaces to complementary surfaces. The assembly step of connecting surface interfaces is here called "seamless covalent welding" and is done in the next higher assembly level (assembly level II?). Seamless covalent welding it usually is irreversible but sparsely linking versions may be reversible.

Delineation – what crystolecules must not be confused with

Crystolecules must not be confused with crystals out of folded up polypeptide molecules aka proteins (that are made today to find the locations of their constituent atoms).

To emphasize the distinction one could use the term "covalent crystolecules".

Related

- Terminology for parts

- For components at different size scales see: Components

- Stroboscopic illusion in crystolecule animations

- Example crystolecules

- nanoparticles

- In place assembly

- putting molecule-fragments together to crystolecules Mechanosynthesis core

- putting crystolecules together to microcomponents Crystolecule assembly robotics

Terms for bigger assemblies of several crystolecules but not yet as big (and disassemblable) as microcomponents

- Diamondoid crystolecular machine element – diamond like structure – See: Diamondoid

- Crystolecular machine element – more general gemstone like structure – See: gemstone like compound

- assembled from molecule fragments

- assembled to crystolecular elements

- assembly is typically irreversible

External links

At K. Eric Drexlers website:

- A shaft in a sleeve can form a rotary bearing

- Sleeve bearings have been designed and modeled in atomic detail (here shown minus the stroboscopic illusion)

- structural elements

- machine elements

- Design of Nanomachines using NanoEngineer-1

- "Nanomachines: How the Videos Lie to Scientists" (archive) (old dead link)

- without stroboscopic illusion: Molecular dynamics simulation of small bearing design

- A Low-Friction Molecular Bearing Assembly Tutorial, v1