Difference between revisions of "Acetylene sorting pump"

(→Related: improvements) |

(→Related: added Molecule sorting zone) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 53: | Line 53: | ||

== Related == | == Related == | ||

| + | * [[Molecule sorting zone]] | ||

| + | * [[Pumps]] | ||

* [[Acetylene]] – the [[resource molecule]] this pump to designed to transport filter and sort | * [[Acetylene]] – the [[resource molecule]] this pump to designed to transport filter and sort | ||

* [[Polyyne rods]] – used to expel the molecules from the binding pockets in this particular sorting pump design. | * [[Polyyne rods]] – used to expel the molecules from the binding pockets in this particular sorting pump design. | ||

Latest revision as of 08:32, 30 August 2022

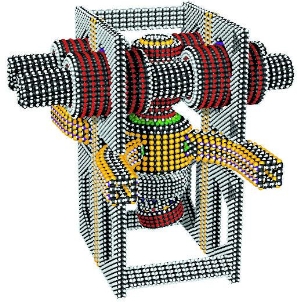

An acetylene sorting pump (or ethyne sorting pump) is a proposed form of "Sorting rotors" to filter the potential resource molecule ethyne (aka acetylene) to ultra high purity for further processing.

Since sorting rotors or (something equivalent in function) are a core critical component of the proposed far term target of gem-gum factories, these where investigated in a bit more detail than other system parts.

Specifically an atomistic model of an acetylene sorting pump with the software Nanoengineer-1 was created. This was the biggest and most complex modeled molecular machine element designed so far (at time of writing 2021). It contains several structural crystolecules that are combined in a way that allows complex relative motions in a superlubricating way (no snapback).

(wiki-TODO: Check if the the original molecular data for this model can still be attained. There seems to be only one low resolution screen-capture left on the web.)

Contents

Some discussion of design aspects

The acetylene sorting pump is a larger diamondoid machine element (DMEs). The frame is one big monolithic crystolecule (it may be fused together via seamless covalent welding during assembly). Other parts are smaller independent crystolecules that may be mechanosynthesized fully passivated as a whole and integrated as a whole without any seamless welding.

Critical aspects of the semi diamondoid parts of the design

The ethyne molecules need to want to go into (and through) the narrow supply channels. In other words a lower energy state is desired within the supply channels. Has this been analyzed or simulated? Nanoscale channels can sometimes cause some odd effects like high temperature freezing. If ist works. How efficient can this be made? How low of an energy drop is sufficient for molecules being transported efficiently?

What about binding energy the specificity of the binding pocket (CO2 is somewhat similar in shape and size) – there probably where investigations

Possible critique points (for this specific proposed design):

Due to the integrated ethyne rods:

- possibly higher radiation damage sensitivity.

- parts possibly quite a bit more difficult to synthesize

Interesting aspects of the diamondoid parts of the design (less critical)

- The drive rods featuring a helical design and running in cyclindrical guides that give only radial support.

- The worm drive. This was the first time such a diamondoid molecular machine element was modelled (to the authors knowledge).

- Sparse strained shell to frame transition

- How much may ethyne rods flex before them becoming too reactive and potentially sometimes covalently bonding to a guide-wall?

(wiki-TODO: Find out if there was some reasoning behind gearing down an how much.)

Possible alternatives (for this specific proposed design)

Are there alternative solutions?

Without the rods pushing the molecules out of the pockets actively

it may be doable via thermal means. The issue here though is that:

(1) Big thermal differences should equate to big (macroscopic) spacial distances stretching out the design massively. Big distances allow for good thermal insulation and thermal energy recuperation.

(2) There are several purification stages to go through. So this long distance needs to be bone through several times back and forth.

Related

- Molecule sorting zone

- Pumps

- Acetylene – the resource molecule this pump to designed to transport filter and sort

- Polyyne rods – used to expel the molecules from the binding pockets in this particular sorting pump design.

- Carbon dioxide sorting pump

- Nanoengineer-1 – the software used to design this model

- Examples of diamondoid molecular machine elements#Wormdrive gearbox – worm drive

In the concept animation video Productive Nanosystems From molecules to superproducts

the acetylene sorting pump system is the very first step shown and visualized in a very simplified way

(cross section exposing polyyne rods)