RepRec pick-and-place robots (GemGum)

| 50px | This page is part of the RepRec project. Short for Replicating Recomposer Systems. For an index of all pages of this project, see the category page RepRec. |

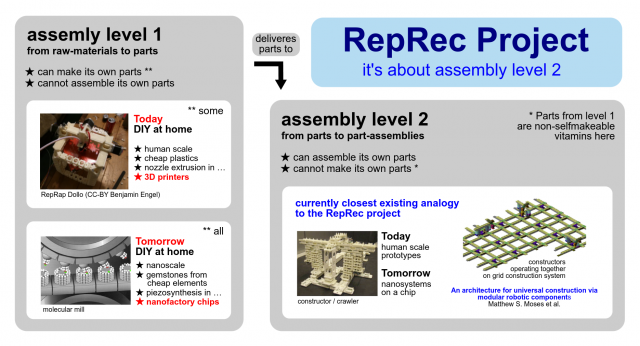

In general context RepRec systems are (per definition) a class of self replicating pick and place robotic systems ...

- that do not produce their own parts but instead use parts pre-produced by a different process

- that do assemble copies (and improvements) of themselves from the same types of parts that they are themselves composed out of.

In the specific context of advanced atomically precise manufacturing i.e.

gemstone metamaterial technology RepRec systems ...

- constitute the second assembly level in a gemstone metamaterial on chip factory

- are much more amenable to prototyping at the macroscale for the nanoscale.

See: Applicability of macro 3D printing for nanomachine prototyping

Closest currently existing project is:

"An architecture for universal construction via modular robotic components" by Matt Moses et.al.

[1]

There are quite some major differences though to make it work in the context of nanoscale physics with crystolecules as building blocks.

More on that further below.

Factored out sub-project: ReChain frame systems

Contents

[hide]A note on selfreplicativity (brief)

While with "second assembly level self replication" there is a medium compact form of self replication present

the self replicative capability is not as compact as in the case of the molecular assemblers approach.

Molecular assemblers are outdated because of too compact self-replications and the consequences thereof.

More detailed notes on that at further down.

Base block materials the design is aimed at

Reusable crystolecules

The design is:

- particularly targeted towards reusable fully passivated crystolecules as the pre-produced base parts.

- not targeted towards partially passivated crystolecules that get irreversibly welded together to bigger microcomponents.

Foldamer parts?

Pre self-assembled foldamer parts with high geometry might eventually work too as base parts.

Given they are stiff enough. But this is questionable. If it works it will be quite a bit bigger than in the crystolecule case.

Unfortunately the parts that structural DNA nanotechnology can make are almost certainly not stiff enough.

Macroscale prototypes

For prototyping functionality at the macroscale FDM 3D printing or resin 3D printing are possible options.

Of course one needs to keep an eye on: Applicability of macro 3D printing for nanomachine prototyping

Look at mechanical property transposition for comparability.

Eventual macroscopic use cases of the system (as home device beside a RepRap or as a device for truss construction in space)

can't be excluded but optimization for those applications is definitely not the design goal here.

heavy chains instead of drive belts and other design choices might make the system quite sub-optimal for those alternate application cases.

Key properties

Same as the ReChain frame systems that may serve as a basis.

Narrow range of part sizes

All parts are in a narrow size range.

There is not a range from very small connectors to very big plates.

Instead bigger parts are made up out of many smaller parts

This allows to keep all assembly activity to just a single (the second) assembly level.

No dependence on friction based self holding

A dedicated nanoscale friction element:

- is solely used for deliberate energy dissipation

- can not beused for friction self holding

- is more like a tuning fork in vacuum that after being plugged (see: snapback) distributes its excitation into overtones and eventually the mounting surface.

This "flowout" called dissipation (to more degrees of freedom) and is driven by the forks anharmonicity ~ deviation from linearity of the restoring force.

There is no friction at the nanoscale between atomically precise surfaces in the way as there is friction at the macroscale.

So screws won't hold in the same way as they do at the macroscale.

Matching up atomic surface waviness can hold things in place, yes, but that's an energetic barrier rather than static friction.

Bulky design

There are a few reasons for bulky design.

- To compensate for the low stiffness of all materials at the nanoscale. Necessary only for suppressing deflections from thermal motion.

Deflections from machine accelerations at the proposed speeds of a few mm/s are very much insignificant. - To make sure all the parts can be handled with robotics of only one (the second) assembly level. Giving a narrow size range between smallest and biggest parts.

- The design happening at the lower end of the physically possible size scales. Details see below.

On bulkiness originating from designing on the lowermost physically possible size limit

When the functional crystolecule pieces are already at the lower end of what physics allows for,

then pieces for connecting parts together cannot by yet smaller since this would make them smaller than an atom.

This pushes the size of the connection mechanisms and similar up into the size scale of the parts they connect.

This is very much unlike the macroscale where e.g. large pieces are often held together by screws,

splint rings or other means that are really quite small in relation.

Choice of name

The name RepRec was chosen in analogy to the name RepRap (Replicating Rapid Prototyper)

that refers to partially self replicating 3D printers.

RepRec stands for Replicating Recomposer

as it can recompose recomposable components.

The name "RepRec" is a name for a whole class of robotic systems.

Akin to RepRap not referring to one specific 3D printer but a whole class of them.

A note on selfreplicativity (details)

Huge differences to diamondoid molecular assembler concept

The self-replicative capability in RepRec systems is not to confuse with

the ultra compact self-contained selfreplicativity in the

outdated concept of molecular assemblers where self replication

is a necessary prerequisite for the bootstrapping of the technology.

In RepRec systems the situation is reversed.

Self-replicative capability is more an eventual consequence of bootstrapping towards

advanced productive nanosystem systems without having self-replicative capability yet.

There is no "proto (diamondoid) RepRec" concept like

there is the "proto(diamondoid) molecular assembler" concept.

Unlike molecular assemblers crystolecular RepRec systems ...

- do not need to be ultra compact to be buildable via positional assembly nigh atom by atom in reasonable timescales.

- do depend on pre-produced parts that is: Crystolecules ... (some caveats here)

- do constitute only a part of an eventual advanced productive nanosystem

- do have a modular static (but reconfigurable) scaffolding frame system an integral non-removable part of their system – see: ReChain frame systems

- may even depend of multiple different semi-mobile units to achieve full selfreplicativity (disributed selfreplicativity)

Advantages of reasonable compact selfrepicative capability

Remaining reasonable compactness of selfreplicativity in RepRec seems like a strong and good driver to

highly reusable/recyclable general purpouse parts and components.

Remaining compactness of self-replicativity in RepRec systems involves:

- a nanofactory chips "pixel" being fully self-replicative not needing the whole chip

- the second assembly level alone being having self-replicative capability not needing the third assembly level for it (not a strong constraint)

The results from such constraints may be well designed systematic sets component parts.

In a sense similarly to standard electrical components just for mechanical systems

(and thus richer as mechanical voltages aka forces come as vectors rather than scalars).

Standard mechanical components for generality and reusability rarely make sense at the macroscale as the overhead is to high.

Macroscale mechanical systems (like clockworks and transmission gearboxes) are small scale one off solutions amenable to heavy optimization.

Like a very specialized analog circuit in electronics.

Prototyping with lego-technic (which is not at all good system for the nanoscale for various reasons btw) may be one exception.

Standard mechanical components for generality and reusability do make a lot of sense for nanosystems

where the complexity approaches the one on that is present on the computer chips of today (2023).

Oddly satisfying construction kits

Good sets of mechanical standard components

may have the quality of being "oddly satisfying".

Kind of like fidget toys.

Not sure if that emotional response can be used as

a gauge for "quality" in any sense and if it can be quantified.

Related

- ReChain frame systems – factored our sub-projects

- ReMec project – overarching umbrella project also including mechanical analog circuits and such

- Second assembly level self replication

- Applicability of macro 3D printing for nanomachine prototyping

- Self replication

Up: RepRec pick-and-place robots in different contexts.

MechanicalThroughJointThreading

External Links

RepRec pick and place robots – on the RepRap wiki

There more kept in the context of usage at home in conjunction with a RepRap

which is actually not the primary design target.

Remotely related:

Project Quine:

- https://projectquine.substack.com/

- https://www.youtube.com/channel/UCWmAvYrypYI8u_w5nJGb_CA/featured

- https://twitter.com/ProjectQuine

Ambots:

Replimat: