Difference between revisions of "Same absolute speeds for smaller machinery"

m (→Related) |

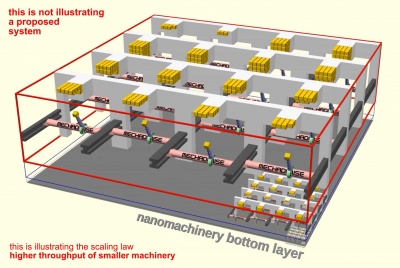

(added illustrative graphic, same as on page Higher throughput of smaller machinery) |

||

| (7 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | [[File:ConvergentAssemblyThroughputScalingLaw-compressed.jpg|400px|thumb|right|In this screencap of an animation the base assumption is "[[same absolute speeds for smaller machinery]]" (leading to linearly higher frequency of smaller machinery) this is only good as a first crude approximation. In an actual system one will want to slow down at the smallest scales, thus this geometry does not correspond to an actually proposed system, at least not at the smallest scales. More infos to this grapic on the page: [[Higher throughput of smaller machinery]].]] | ||

| + | |||

'''Constancy as the natural scaling option for speed of operations of machinery''' | '''Constancy as the natural scaling option for speed of operations of machinery''' | ||

What are the motivating factors to keep speed of machinery motions constant across scales (as a first approximation)? | What are the motivating factors to keep speed of machinery motions constant across scales (as a first approximation)? | ||

| − | * Keeping relative scale deflections from machine motions constant across scales | + | * Keeping relative scale deflections from machine motions constant across scales (see: [[Same relative deflections across scales]]) |

* Keeping friction losses constant across scales | * Keeping friction losses constant across scales | ||

As it turns out both imply constant speeds across scales. <br> | As it turns out both imply constant speeds across scales. <br> | ||

| Line 73: | Line 75: | ||

* [[Scale natural frequency]] | * [[Scale natural frequency]] | ||

| + | ---- | ||

| + | * [[Scaling law]] | ||

| + | ---- | ||

| + | * '''[[Same relative deflections across scales]]''' | ||

| + | * '''[[Higher throughput of smaller machinery]]''' | ||

[[Category:Scaling law]] | [[Category:Scaling law]] | ||

Latest revision as of 11:27, 15 September 2024

Constancy as the natural scaling option for speed of operations of machinery

What are the motivating factors to keep speed of machinery motions constant across scales (as a first approximation)?

- Keeping relative scale deflections from machine motions constant across scales (see: Same relative deflections across scales)

- Keeping friction losses constant across scales

As it turns out both imply constant speeds across scales.

There's a caveat for the latter motivating some deviation from constancy.

A "tiny" bit of intentional slowdown. ("Tiny" meaning less than linear.)

Potential trapdoor to comprehension: Here "absolute speeds" refers to motion in terms of m/s (using SI units)

It does not refer to frequencies (in Hertz or 1/s). For frequencies see: Scale natural frequency.

⚠️ One may colloquially say "smaller machinery moves faster" but in that case one is actually referinng to operation frequencies!

Contents

Keeping relative scale deflections from machine motions constant across scales

Keeping absolute speeds constant across scales

(or in other words keeping the same absolute speeds for smaller machinery)

can be considered as a natural choice when the main motivating factor is:

Same relative deflections across scales

Keeping friction losses constant across scales

While one might expect losses to go up due to

the well known scaling law of twice the surface area of half the volume applied to bearing area,

there is also the compensating factor of

the poorly known scaling law of Higher throughput of smaller machinery.

Both of these scaling laws are linear.

Thus for machinery of scale invariant throughput density and scale invariant operation speeds

they exactly compensate.

(wiki-TODO: Maybe bring this into a more formalized math form to make the point more clear.)

Important caveats – Leading to scaling of speeds that differ from constancy

Alternate natural scaling options for speed of operations of machinery.

Since dynamic friction scales quadratically with speed (Hundredfold smaller frictionlosses from tenfold slowdown) and

Productive nanomachinery takes up very little volume (Higher throughput of smaller machinery)

it is possible to cheat by trading decreased speeds for increased volume of nanomachinery.

See:

- Deliberate slowdown at the lower assembly levels

- Increasing bearing area to decrease friction

- Optimal sublayernumber for minimal friction

Also: Optimal bearing technologies across scales likely change.

This makes deviating a bit from constant speeds across scales desirable.

See: Mesoscale friction

Dispelling eventual concerns regarding convergent assembly

Adding convergent assembly levels atop that are exponentially growing in size

only adds at best logarithmic amounts of additional friction.

Thus it for the most part can be ignored.

Discussion of an perhaps counterintuitive aspect of constant speeds across scales

When conceptually for visualization scaling up just space but not scaling time,

then the assumption of constant speeds across scales leads to magnified models featuring magnified speeds.

One might intuitively expect increased wear and such, but this is misled.

High encounter frequencies are just natural at small scales (Scale natural frequency).

One should remember that even today's macroscale roller bearing in the end feature nanoscale surface-on-surface contacts.

The only change when going to bearings that as a hole are at the nanoscale is

that they necessarily need to be atomically precise because

the wear of imprecisions of the scale of today's macroscale bearings would annihilate nanoscale bearings instantly.

Or rather imprecisions of the scale of today's macroscale bearing can be bigger than whole nanoscale bearings.

Related: Intuitive feel