Difference between revisions of "Superlubricity"

(massive update part 1/?) |

(added sections) |

||

| Line 18: | Line 18: | ||

* [[diamondoid]] molecular bearings and other [[diamondoid molecular elements|DMEs]] with sliding interfaces. | * [[diamondoid]] molecular bearings and other [[diamondoid molecular elements|DMEs]] with sliding interfaces. | ||

* an advanced [[metamaterial]] forming an [[infinitesimal bearing]] structure. | * an advanced [[metamaterial]] forming an [[infinitesimal bearing]] structure. | ||

| + | |||

| + | == Dynamic drag in superlubricating gemstone bearings - vs - viscous drag in liquids == | ||

| + | |||

| + | '''There is at least 2000 to 100000 times less friction in gemstone bearings compared to movement at the same speed in water.''' <br> | ||

| + | |||

| + | So when it comes to peak performance parameters <br> | ||

| + | soft nanotechnologies and artificial [[synthetic biology]] derived from molecular biology, <br> | ||

| + | is fundamentally massively inferior to [[gemstone metamaterial technology]] | ||

| + | |||

| + | Yes, this much lower friction is still more than the zero friction that is as present in diffusion transport. <br> | ||

| + | But this misses a crucial point. <br> | ||

| + | For diffusion transport to happen it still needs to "expend" energy (still needs to devaluate free energy). <br> | ||

| + | It is just that the free energy expense need to be payed up at the pitstops (when crossing cell- and vesticle-membranes) rather than during the transport motion. (see external links) | ||

| + | |||

| + | So: <br> | ||

| + | '''Diffusion transport driven by concentration gradients does NOT make biological nanosystems fundamentally more efficient than conveyorbelt style transport in stiff dry artificial nanosystems in a vacuum.''' | ||

| + | |||

| + | == Dynamic drag can be significant == | ||

| + | |||

| + | While static friction in superlubricity falls to nigh zero, <br> | ||

| + | This is very much not the case for dynamic (speed dependent) friction. | ||

| + | |||

| + | For higher speeds and bearings that do not resort to: | ||

| + | * [[levitation|some mean of levitation]] ( only possible for low loads ) or | ||

| + | * [[infinitesimal bearings|bearing stratification]] ( only possible for bigger nearings ) | ||

| + | ... the friction per area can actually get quite high for higher speeds. | ||

| + | |||

| + | {{whikitodo|Insert numbers/table!} | ||

| + | |||

| + | But: <br> | ||

| + | ① Halving the linear speed (in units of m/s) quaters the friction losses. <br> | ||

| + | And going down from 1m/s to 1mm/s the friction losses fall by a factor of a million (1,000,000). <br> | ||

| + | More technically: Dynamic friction for crystolecules scales quadratically with speed. <br> | ||

| + | |||

| + | ② One totally can afford to slow down so much in advanced productive nanosystems liek gem-gum factories <br> | ||

| + | because there is plently of space to compensate by just adding more nanomachinery. | ||

== Superlubricity - vs - Superconductivity == | == Superlubricity - vs - Superconductivity == | ||

| Line 27: | Line 63: | ||

* Superlubrication is reached by decrease of degree of intermeshment while superconductivity is reached by decrease of temperature. | * Superlubrication is reached by decrease of degree of intermeshment while superconductivity is reached by decrease of temperature. | ||

* There is not a sharp cutoff in friction when decreasing the degree of intermeshment like the cutoff in superconductivity when decreasing temperature. | * There is not a sharp cutoff in friction when decreasing the degree of intermeshment like the cutoff in superconductivity when decreasing temperature. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Thermal activation energy - vs - Angular energy wavyness == | == Thermal activation energy - vs - Angular energy wavyness == | ||

Revision as of 11:33, 15 September 2021

Up: Friction in gem-gum technology

Superlubricity (or superlubrication) is a state of extremely low friction that occurs when two atomically precise surfaces slide along each other in such a way that the "atomic bumps" do not mesh.

More precisely: When the lattices distances projected in the direction of movement are maximally incommensurate.

Contents

- 1 Key aspects of superlubricity

- 2 Examples exhibiting superlubricity

- 3 Dynamic drag in superlubricating gemstone bearings - vs - viscous drag in liquids

- 4 Dynamic drag can be significant

- 5 Superlubricity - vs - Superconductivity

- 6 Thermal activation energy - vs - Angular energy wavyness

- 7 Choice of nanoscale passivation and snapback dissipation

- 8 Main power dissipation mechanisms

- 9 Superlubricating crystolecule machine elements

- 10 Snapping into place

- 11 Quantum effects in (rotative) gemstone nanomachinery

- 12 Related

- 13 External links

Key aspects of superlubricity

- Present in gem-gum-tec: Superlubricity is present in crystolecule bearings which are essential molecular machine elements in gemstone metamaterial technology.

- Eternally wear fee: Superlubricity features no "collinding mountainranges" at the nanoscale that can mutually shear off their tips. Thus superlubricating bearings are fully wear free. The dominating damage mechanism of superlubricating bearings is ionizing radiation or thermal destruction in extreme conditions (melting, evaporationg, hot chemical dissolution, ..). There is damage over time but there is no wear from mechanical friction (and load) over time.

Examples exhibiting superlubricity

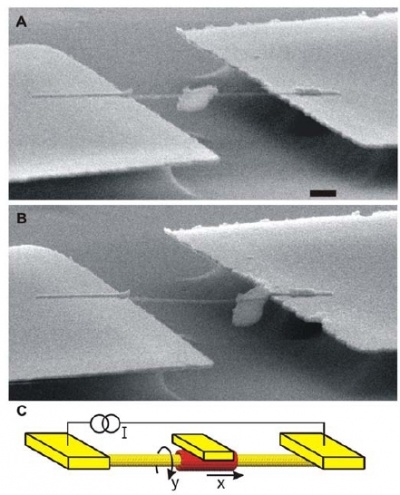

- two coplanar sheets of graphene rotated to one another to minimally mesh

- two appropriately chosen tightly fitting coaxial nanotubes (experimantally demonstrated) (wiki-TODO: add reference)

- diamondoid molecular bearings and other DMEs with sliding interfaces.

- an advanced metamaterial forming an infinitesimal bearing structure.

Dynamic drag in superlubricating gemstone bearings - vs - viscous drag in liquids

There is at least 2000 to 100000 times less friction in gemstone bearings compared to movement at the same speed in water.

So when it comes to peak performance parameters

soft nanotechnologies and artificial synthetic biology derived from molecular biology,

is fundamentally massively inferior to gemstone metamaterial technology

Yes, this much lower friction is still more than the zero friction that is as present in diffusion transport.

But this misses a crucial point.

For diffusion transport to happen it still needs to "expend" energy (still needs to devaluate free energy).

It is just that the free energy expense need to be payed up at the pitstops (when crossing cell- and vesticle-membranes) rather than during the transport motion. (see external links)

So:

Diffusion transport driven by concentration gradients does NOT make biological nanosystems fundamentally more efficient than conveyorbelt style transport in stiff dry artificial nanosystems in a vacuum.

Dynamic drag can be significant

While static friction in superlubricity falls to nigh zero,

This is very much not the case for dynamic (speed dependent) friction.

For higher speeds and bearings that do not resort to:

- some mean of levitation ( only possible for low loads ) or

- bearing stratification ( only possible for bigger nearings )

... the friction per area can actually get quite high for higher speeds.

{{whikitodo|Insert numbers/table!}

But:

① Halving the linear speed (in units of m/s) quaters the friction losses.

And going down from 1m/s to 1mm/s the friction losses fall by a factor of a million (1,000,000).

More technically: Dynamic friction for crystolecules scales quadratically with speed.

② One totally can afford to slow down so much in advanced productive nanosystems liek gem-gum factories

because there is plently of space to compensate by just adding more nanomachinery.

Superlubricity - vs - Superconductivity

The name "superlubricity" points to some weak analogies to superconductivity:

- similar: It is also a state of low energy dissipation during the motion of elemental particles

- dissimilar: It has no sharp onset/cutoff point and friction does not fall to unmeasurably low levels

- dissimilar: It is present at all (non destructive) temperatures including ~300K room temperature

- Superlubrication is reached by decrease of degree of intermeshment while superconductivity is reached by decrease of temperature.

- There is not a sharp cutoff in friction when decreasing the degree of intermeshment like the cutoff in superconductivity when decreasing temperature.

Thermal activation energy - vs - Angular energy wavyness

If AP surfaces are designed or aligned to not mesh then the "perceived bumps" (the bumps that the surfaces perceive as a whole) become lower and their spacial frequency becomes higher (more bumps per length). If the surface pressure isn't extremely high the characteristic thermal energy kBT can become a lot higher than the bumps energy barriers. Thus the (static) friction becomes so low that e.g. an unconstrained DMME bearing can be activated thermally and may starts turning randomly in a Brownian fashion [to verify].

Choice of nanoscale passivation and snapback dissipation

Oxygen or sulfur with their two bonds in a plane parallel to the relative sliding direction are a good choice for surface termination of bearing interfaces since this configuration gives maximal stiffness in sliding direction.

If the two bonds of the atoms are instead in a plane normal to the sliding direction the lower stiffness may lead to higher energy dissipation (friction). Singly bonded hydrogen fluorine or chlorine passivations have even lower stiffness, see: E. Drexlers's blog: snap back dissipation. This can be deliberately used in dissipative elements (friction brakes). There's a critical point at which snapping back starts to occur [todo: simulation results needed].

Main power dissipation mechanisms

(TODO: Integrate infos from Nanosystems and the "evaluating friction ..." paper.)

Main article: Friction mechanisms

Superlubricating crystolecule machine elements

Atomically precise gemstone bearings

Interestingly Van der Waals forces allow for stable designs in which the axle in gemstome bearings is pulled outward in all directions instead of compressed inward.

This allows for lower friction at the cost of less load bearing capacity.

Stretching terminology a bit this could be counted as one form of Levitation.

- Q: How much can friction be lowered by this strategy?

- Q: Might resonant vibrations start to occur at high operation speeds?

Atomically precise gemstone gears

Gears with straight rows of teeth, while reducing atomic bumps due to being roughly shape complementary, do not smooth out atomic bumps beyond that.

Helical gears in contrast can smooth out and do smooth out atomic bumps.

Up to some point the longer the contact between gear teeth the better the smoothing.

This is a motivation to not make gears at the absolute minimal size possible but a bit above that.

As a side-note: Another reason for making gears a bit above the absolute minimal size is that stiffness of the intermeshing gear teeth interface can be matched to the stiffness of the axles (preventing flex wave reflections in higher frequency operations).

Rods in sleeves

Challenges:

- Using the same material for rod and sleeve can lead to pretty much the same spacing and no good superlubrication.

- Getting a fit of just the right tightness with a compact sleeve around a thin reciprocative rod may be more difficult than getting just the right fit with a big stator sleeve around a big diameter rotor. Bigger loops can be finer adjusted in a relative sense.

Snapping into place

As mentioned before there is always a slight remaining ripple in the position dependant potential energy of the bearing (in its potential energy surface - PES). This energy corresponds to the (very low) temperature under which the bearing starts to snap into place. (If quantum zero point energy isn't too high?)

Quantum effects in (rotative) gemstone nanomachinery

Quantisation of angular momentum is usually not present except for very small free rotating elements at very low temperatures. Axels in nanomechanical systems are usually coupled to a bigger system making their moment of inertia rather big. Free rotations will often be suppressed which leaves only torsional vibrations as possible degree of freedom.

See:

Related

- More friction due to rising surface area.

- Less friction: How friction diminishes at the nanoscale.

- Gem-like molecular elements or for short on this wiki here: crystolecules

- Superlubrication goes perfectly together with infinitesimal bearings, reducing friction even further.

- Negative pressure bearings

- Levitation

- Superelasticity ... another performance parameter that can be unusually elevated at the nanoscale

External links

Related pages on E. Drexlers homepage (internet archive):

- Phonon drag in sleeve bearings can be orders of magnitude smaller than viscous drag in liquids

- Symmetric molecular bearings can exhibit low energy barriers that are insensitive to details of the potential energy function

- Stiffly supported sliding atoms have a smooth interaction potential

- Softly supported sliding atoms can undergo abrupt transitions in energy -- Related page: Snapback

- Paper: "Evaluating the Friction of Rotary Joints in Molecular Machines" (2017-01-27)

arXiv:1701.08202 [cond-mat.soft]; ResearchGate; pubs.rsc.org; Google Scholar

This uses simpified results from the Fluctuation-dissipation_theorem (Wikipedia-link)

- Zyvex: A Proof About Molecular Bearings by Ralph C. Merkle -- 1993

- Wikipedia: Superlubricity

- Wikipedia: Carbon nanotube nanomotor

- Experiments with nanotubes: Superlubricity on the macroscale