Difference between revisions of "Infinitesimal bearing"

m |

|||

| Line 12: | Line 12: | ||

[TODO: design a makro model structure for demonstration] | [TODO: design a makro model structure for demonstration] | ||

| + | |||

| + | == == | ||

| + | |||

| + | Doubling the number of layers and thus halving the speed leads to halve the friction since the doubled surface is compensated by | ||

| + | |||

| + | |||

== Related AP metamaterials == | == Related AP metamaterials == | ||

Revision as of 11:14, 14 January 2015

APM in T.Level III may enable us to create a new type of macroscopic bearings in the form of a passive metamaterial.

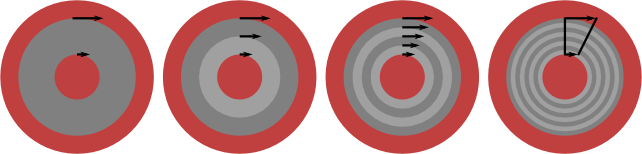

To reduce the relative speed of two surfaces one stacks many layers with minimal thickness (each layer un-percievably small - thus "infinitesimal"). Just enough to accommodate some necessary nanomechanics. Those nanomechanics are DMME gears (not bearings) and further structure that make sure that every layer takes the same part of the total speed difference. Note that due to superlubrication a single layer can take well perceivable macroscopic speeds without being destroyed thus bearings replacing todays macroscopic ones will need to use only a very thin stack of infinitesimal bearing layers. Since there's no static friction and very low speed dependent dynamic friction in diamondoid nanomechanics (see superlubrication) the bearings efficiency can be expected to be exceptional.

It is to investigate how a macroscopic infinitesimal bearing performs relative to nanoscopic DMME bearing and how long an infinitesimal brearing of certain size would turn till it e.g. reaches half its initial speed.

As in all products of advanced nanosystems the nanomechanics must (through their structure) provide some redundancy making the design more complicated

[TODO add more detailed Model]

[TODO: design a makro model structure for demonstration]

Doubling the number of layers and thus halving the speed leads to halve the friction since the doubled surface is compensated by

Related AP metamaterials

Adding chemomechanical or electromechanical motors into the layers changes it into an interfacial drive (an active metamaterial). There the add-up of layer movement acts as one of the methods to accumulate nano motion to macroscopic levels (mechanical macroscopification).