Introduction of total positional control

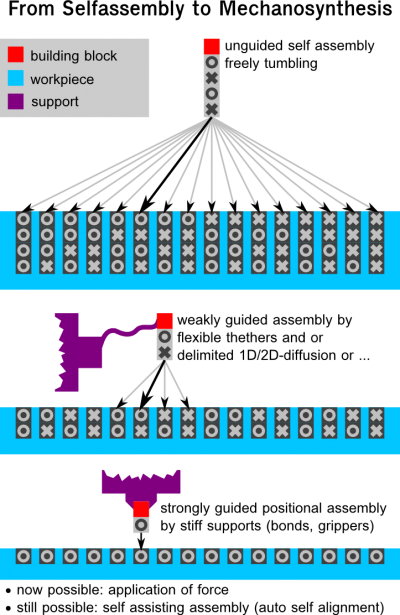

Introduction of robotic control that is unassisted by self assembly to atomically precise building block structures.

Introduction of total positional control is the step from technology level 0 to technology level I on the incremental path to APM.

- (wiki-TODO: mention (and analyze) that method which uses pseudo-self-assembly after surface activation under total positional control)

Contents

- 1 Details

- 2 Experimental equipment

- 3 Big lab R&D vs citizen R&D

- 4 Useful rigid sub micro components

- 5 Design Parameters

- 5.1 Choice of bootstrapping method

- 5.2 Few parts or many parts?

- 5.3 exclusively rotative DOFs or inclusion of translative DOFs

- 5.4 serial or parallel mechanics

- 5.5 dimensionality 3D or 2D+1D

- 5.6 rotative and translative manipulation combined or separated

- 5.7 Exoergic chain

- 5.8 Method for mechanism actuation

- 5.9 digital stepping drive or analog drive

- 5.10 Misc

- 6 Concrete example proposals for the step from T.Level 0 to 1

- 7 Goal

- 8 Related

Details

For positional control one needs robotic base parts. Without positional controls available yet we need to rely on self assembly and conventional chemistry alone to make these base parts.

Most of the robotic base parts (needed for the introduction of positional control) consist out of structural (non functional) material where we don't care too much about their inner structure. We mostly care about their outer limits (their shape). The inner structure just needs to provide sufficient stiffness. The inner structure can contain arbitrary complexity. That is the inside structure can be built from diversely shaped mutually fitting "puzzle pieces" without disturbing the outer potentially much simpler shape and function. The outer shape may even follow a simple Cartesian (right angled) design. This freedom for the parts interior design is exactly what we needed for self assembly.

By now multiple methods have been found (and successfully demonstrated) that are capable of self assembly of parts that may be usable as the needed robotic base parts. Some of these structures do not follow natures complex low symmetry design but rather go into a direction where the parts look much more right angled symmetric and have more machine like geometries. It is much easier to reason about and design with such more symmetric artificial structures.

Right angled "DNA snippet minecraft"

One of the newly found methods that uses short DNA-snippets (oligomeres/oligos) has a structure like a wire-mesh-fence but in three instead of two dimensions. (wiki-TODO: add reference to DNA brick paper) Each DNA-snippet behaves like a binary voxel (3D-pixel) in a 3D-drawing-canvas (think: minecraft) The DNA-snippets code is equivalent to the 3D-target coordinates in encoded form. To make arbitrary shapes one simply mixes only the DNA-snippets that correspond to the voxels one wants to set. This suffices for the creation of robotic components. Or at least parts of them if the structures are so big that the available address space is insufficient.

The DNA-snippet voxels are called "DNA-bricks". Assemblies from them are the first example that provides this level of programmability. But as mentioned they are limited in size. Adding address space would prolong the DNA-snippets thereby making the wiremesh-fence loops longer/bigger and the structure would lose too much stiffness.

hierarchical self assembly

Main article: Convergent self-assembly

If the limit of addressable size space can't be overcome (changing the blocks aspect ratio may help a bit) then hierarchical self assembly can help. After small robotic base parts have self assembled they themselves can be self assembled if they where designed with complementary surfaces and brought in the right environmental conditions. (Reversible second level self assembly has been demonstrated with changement of salt concentration. An amazing feat (wiki-TODO: add link to hierarchical self assembly paper)).

It's worth noting that second level self assembly (to larger structures) is quite different from first level self assembly. While complementarity needs to be introduced again (drop in symmetry) the engineering like cartesian (right angled) base geometry is retained. The pieces here are not treated simply as voxels like in the self assembly of the DNS-bricks but can have functional outer structure that can remain exposed.

Second level self assembly interfaces may have lower stiffness than the parts internal first level self assembly stiffness.

Beside DNA based binary "voxelated" bricks other more or less similar methods are already available and more will be upcoming.

assembly with etched out microrobotics

Beside further self assembly in a second hierarchical step (reduced brownian mobility of the bigger molecular assemblies can become a problem here). to further assemble small scale binary voxelated bricks (of any sort) to rigid parts there's also a second possibility.

Direct non atomically precise micromachine robotics (taking a short-cut). For this the parts need to get into machine phase first (more about that below). The problem here is the smallness of MEMS must overlap the bigness of the self-assembled structures. This is not yet the case. While there is a noticable size overlap with professional electronic microchip size easier accessible microelectronic production facilities and MEMS production in general does not show usable overlap yet. At the point a size overlap arises a combination of both approaches partial self assembly followed by robotic MEMS assembly is likely.

self assembled hinges (restriction of complicance to local spots)

Self assembly of hinges has been demonstrated (wiki-TODO: add link to DNA hinges paper)

Using self assembly to create sturdy structures with (interlocking) hinges though has not yet been demonstrated and may be too tough of a problem such that after creation of the complete rigid parts robotic assembly of them seems to be a good approach.

self assembled pre-ordering for robotic bootstrapping

Assuming basic rigid body robotic parts e.g. rods with eyelets for linkages (or even assembled linkages) are buildable via self assembly then to assemble them robotically e.g. via exponential assembly one needs to know their exact locations. They need to be in the machine phase.

Beside their non robotic usefulness as "molecular breadboards" Modular Molecular Composite Nanosystems (MMCS) might be useful to lay out those pre-self assembled functional components in an ordered fashion so that exponential assembly could be done.

part type testing approach

Otherwise if one operates with the parts scattered randomly on a surface one somehow must pick the parts up check which type they are sort and store them - a rather complicated procedure. For this approach a more self replicating approach than exponential assembly might be suited better. Simple blocks could be "bulldozed" together for sorting. Bigger parts could be identified by AFM like scanning (which ruins parallelism).

Note: The more basic the structures are which can be handled robotically by the system the more productive this level I nanosystem gets (in the sense that it can produce products that can be fairly different from the system itself). If robotic control isn't voxel-brick based but rigid component based it may be more practical to introduce that capability later on.

Experimental equipment

Synthesis

The price of synthesis for some foldamers like DNA oglionucleotides is continuously falling.

Assembly

For the mixing of self assembling foldamer cocktails. Up till now very expensive big industrial robotic pipetting systems where used. The kind you'd find in big biochemistry labs. A temperature regulated chamber is then used to anneal the cocktails.

Microfluidics systems that manage bubbles like digital data packages (individual reaction chambers) have the potential to drastically increase speed and reduce cost. Such systems can be 3D-printed. It was even demonstrated that it half decently feasible to print microfluidic systems on home grade FDM 3D-printers. (wiki-TODO: add link to microfluidic FDM paper) There are no open-source models for microfluidic systems online yet though (state 2017-04).

Analysis

For analysis of the produced structures the usual methods are:

- scanning probe microscopy SPM (STM / AFM)

- fluorescence microscopy (seeing 10nm far below the diffraction limit of an optical microscope is now possible with some tricks)

- transmission electron microscopy (TEM)

- cryo-TEM-tomography

Small mobile scanning tunneling microscopes (STMs) with atomic resolution on graphite can be built DIY style with a relatively small private budget. There are several project around but they are not yet available as cheap off the shelf "toy" like e.g. 3D-printers. It remains to be seen how they fair when imaging self assembled molecular structures.

Big lab R&D vs citizen R&D

Just like with proprietary and open-source software the two are complementary.

Big company funded R&D usually has a very strong short term profit orientation leaving not much space for aiming at a well visible but far off goals.

State funded R&D also is often profit oriented albeit not as obviously.

But big money R&D is also strongly restricted by the established disciplines.

Low budget citizen R&D can potentially fill a complementary role. The problems that get solved here are (as we know from other areas) are:

- the ones that are interesting but seemingly unprofitable (that does not imply unimportant!) and

- the interdisciplinary problems that sometimes to fall through the cracks of disciplines in state funded research.

Regarding citizen R&D there may or may not be a lack of professionality and there may or may not be a large number of participants.

Citizen R&D though as of yet hasn't taken off in the field of atomically precise manufacturing. Likely because the (conventional) technology isn't ready yet.

One related topic to note here may be the relatively new method of "crowd-sourcing".

Related: "Citizen science"

Useful rigid sub micro components

Size adapters

If AP building blocks can be post self assembled or directly made big enough. It might make sense to create a size adapter that can be gripped by MEMS manipulators on one side and can pick and place single AP blocks with the other side. Thus spanning the top-down bottom-up gap.

The size of the smallest possible MEMS grippers and DNA-bricks aren't overlapping yet [TODO add size comparison], that is the tip radius of the grippers tend to be greater than e.g. DNA-brick sizes. So they need to be aggregated to even bigger sizes to be grippable.

To investigate:

- Can e.g. DNA-bricks be hierarchically self assembled, that is can the blocks surfaces be glued together by adding strands in a second step?

- Alternatively do complementary surfaces stick by VdW interaction even though there are no open strands (or the strands doesn't match)?

Serving plates

To make recognition of the block types easier a set of types could be self assembled to a bigger mounting plate. Designing those serving plates as boxes could provide protection from unwanted self assembly steps like when the building block supply is depleted and the system is reloaded in liquid phase.

Building plates

Flat structures where products can be built on.

Design Parameters

Choice of bootstrapping method

Pure self assembly exponential assembly or fully fledged self replication?

[rough kewords ...]

- replicative: build volume limit -> 2D mobility

- parallel: accuracy issue - effort in parallelization of tips leaves them too imprecise ...

- bulldozing

- pros of dry operation

Mechanical and micro-mechanical systems such as AFMs and MEMS are generally very slow too slow. [TODO add quantitative numbers]

beside the problem of yet unstable tool-tips and insufficient vacuum It seems certain that they are too slow to do direct mechanosynthesis.

To investigate: Will they be fast enough to do e.g. assembly of self assembled AP bricks or bigger parts?

proto-partial-manipulator

Few parts or many parts?

Too few component part types force the parts to be too generic and the resulting systems to be big slow and barely productive. There are some examples of macroscopic self replicating robot approaches that seem to suffer from this (TODO: include examples). Too many component part types would require advanced not yet available systems. It still is unclear what the optimal number of part-types will be for early pre-produced block based productive nanosystems will be.

It makes sense to use some end-effector adapter parts such that the parts do not all need a standard grasping interface. Thus one does not end up with having to encode placeability in all pieces similar to the restriction of self-assembly: encoding place in all pieces.

exclusively rotative DOFs or inclusion of translative DOFs

Manipulators that exclusively feature rotative degrees of freedom have either non-linear motions and complex math or many bearings to create linear or almost linear motion. Mechanism to create perfect linear motion are the three dimensional Sarrus linkage and the seldom used Peaucellier–Lipkin linkage.

Cartesian mechanisms with sliderails have trivial math but may be less stiff and especially with DNA naotechnology may provide a rather bumpy ride much less accurate than a flexible hinge.

Since the surfaces of self-assembled AP blocks are far less smooth than the ones of future DMEs sliding rails for reciprocative movement may lead to risks of destructive clogging and low resolution. Linkages could make use of the already several times demonstrated edge to edge seam hinges for rotative movement instead.

Examples of rail-less robots that avoid spherical joints: Wally, Simpson, Morgan

serial or parallel mechanics

Serial mechanics means that the driving actuators ("motors") are locate in the hinges of the manipulator mechanism. With structural DNA nanotechnology this was demonstrated via shortening a DNA string that pulls on a flexible hinge like a tendon. To shorten the DNA string short DNA snippets (oglionucleotides) where added that can clamp a loop in the "tendon" DNA string. Since this method requires a change of dissolved oglionucleotides it is slow relative to (yet undemonstrated) electrostatic actuation (even in microfluidics). Control is also limited. The closable lengths are discrete and only a pulling action is applicable. Translative movement was also demonstrated by a remotely similar method called DNA walkers. There the amount of control is even lower but it might still prove to be very useful.

Parallel mechanics means that the actuators ("motors") are outside of the manipulator mechanism. Therefore the manipulator mechanism can be a completely passive linkage system.

Serial mechanics with electrostatic actuators in the hinges is probably impossible since the area of capacitor plates must be big enough to overpower thermal motion. The necessary area (relative to the size of the driven part!) for actuation will be smaller than in MEMS systems (comb drives) but will be still to big to be includable directly in the hinges. Also self-assemblable nano circuitry hasn't been demonstrated yet. And electrons behaving ballistic and quantum mechanical at such low scales (in contrast to mechanics) would be likely to make things more difficult - resistance may sharply change with corner angles.

Serial mechanics also leads to actuators looking more like robot arms which are due to their lower stiffness better suited for manipulation tasks on a bigger scale.

Parallel robots can provide mechanical simplicity at the cost of control complexity (inverse kinematics)

Related: rotative only or inclusion of translative

dimensionality 3D or 2D+1D

A fully three dimensional manipulator system has either complex mechanics or complex control.

A two dimensional assembly system may make the manipulator design much simpler. To erect a 3D structure afterwards some post processing manipulation will be needed. For more blocky structures layer by layer coplanar extrusion might work - like an inverse tertis. For more filigree structures a method like erecting superhuman scale trussworks without a crane might work.

rotative and translative manipulation combined or separated

To simplify manipulator design further rotation may be decouplable from translation. A separate rotator mechanism may be usable for rotation in the main directions (100) (110) (111).

Exoergic chain

From the blocks creation to their final destination they have to first get bound into machine phase then have to be picked up and finally be placed down. To archive this either the binding strengths has to strictly monotonically increase from step to step (an exoergic chain) or sterical means have to be employed. ...

When robotically assembling self assembled robotic parts it may be necessary to temporarily pin down levers to prevent them from spinning on their axles and rip them loose when putting them in use.

Method for mechanism actuation

Electrostatic

Todays most advanced nanotechnology is electronics. Driving mechanisms with electrostatic forces is thus an obvious route. Electric fields generated by microelectronics acting on a AP brick structure or an other type of structure in machine phase provide less degrees of freedom than a mechanical gripper but are considerably faster.

To keep the complexity of the mechanical mechanisms low the number of input channels must be kept as high as possible. Since the electric contacts still are rather big compared to AP building blocks one could create mechanical signal collector bundles crossing the electrodes and broadcasting reciprocative movement to a number of mechanisms.

Self assembled AP blocks may be (and probably are) electrically isolating.

Still with strong electric fields local polarizations may be induced and kind of an "stand up hair effect" could be used as driving method.

To investigate: feasibility of this approach.

If the blocks need to be made dielectric or charged to be effected by the field:

To investigate: Can blocks/block structures be made dielectric or charged sufficiently?

To use electric fields as input the block structures need to provide at least one internal 1D degree of freedom which can be compressed to 0D (machine phase). To investigate: How to create minimal sized block structures for mechanical or electrostatical actuation that are productive and capable of structural copying or self replication? The proto-mechanism problem.

Pressure

[Todo: add ref]

digital stepping drive or analog drive

Using a stepping drive means that in effect a local memory must be kept - this means more complexity in hardware. An analog drive may not have sufficient resolution if thermal motion is barely overpowered.

Misc

With basic AP blocks only very simple mechanisms will be buildable.

To be usable for somewhat functional robotic applications the blocks need to fulfil some criteria:

To investigate:

- Can an axle bearing system be built that runs non self destructively with sub block-size precision?

- Can two blocks be connected with a edge to edge hinge? (similar to the hierarchical assembly question)

- Can the blocks bind strong enough together to avoid falling apart when actuated?

- Are the surfaces of DNA-bricks made with half strands, that is are there surfaces smooth or more like a hairy ball) [TODO dig out the known answer]

Concrete example proposals for the step from T.Level 0 to 1

[TODO to myself: add the one I've archived] technology level I

For a partial self replicating system with minimal complexity following components might suffice:

- (electrostatic) actuators of sufficient force to counter thermal noise (-> not smallest scale)

- mechanical broadcast channels to ...

- active locking of mechanical states or if unavoidable (lack of inputs, ...) ratchets

- DEMUX (depending on broadcast channel length and photo-litographic input size this may be avoidable in favour of multiple 4? inputs) (basically nano-mechanical logic here)

- simple parallel manipulator(s) (if it simplifies the design they may be split up and specialized for different DOFs?)

- gripping or expulsion mechanism (exploiting self assisted assembly)

While making assembly easier more complex pre-built base parts can reduce the productivity of a system.

If it proves too difficult to produce AP scaffolds with macroscopic long range order (self assembly in a temperature gradient?) Two stage two stage exponential assembly may solve the problem where the upper layer is built from MEMS with linear DOFs too.

Goal

Related

- Moving from science to engineering

- Thermally driven assembly

- Locking mechanisms

- Mechanosynthesis. Usually mechanosynthesis refers (beside positional control) to formation of covalent bonds by applying force. This will only be introduced with the next step to stiffer materials which allow true positional atomic precision in placement.

- Bootstrapping methods for productive nanosystems

- Self replication